What is HACCP? HACCP (Hazard Analysis and Critical Control Points) is an internationally recognized systematic method of identifying, managing, and controlling significant hazards associated with the manufacture of food, including biological, chemical, and physical.

As part of a properly managed food safety management system, a HACCP plan offers regulators, customers, and the public assurance of your commitment to food safety. Many food safety certifications require you to develop and implement a HACCP plan based on Codex Alimentarius HACCP principles.

What Does HACCP Stand For?

- HACCP stands for Hazard Analysis and Critical Control Points

The HACCP system focuses on prevention rather than reaction to hazards. This method is widely used in food manufacturing and is the basis for prestigious standards such as the Global Food Safety Initiative (GFSI) and related benchmarked certifications, including SQF certification, BRCGS certification, and FSSC 22000 certification.

Many large retailers and quick-service restaurants require a GFSI-benchmarked food safety certification to supply them.

So, if you want to sell your products to large companies, writing a HACCP plan is one of the key steps in a robust food safety system.

What is a HACCP Plan?

The National Advisory Committee on Microbiological Criteria for Foods (NACMCF) defines a HACCP Plan as, “The written document which is based upon the 7 principles of HACCP and which delineates the procedures to be followed.”

As you complete the steps needed to develop a HACCP plan (which we explain below), you will need to document your products and processes, hazard analysis, critical control points, critical limits, and relevant procedures and justifications.

The written document that results from this work is your HACCP plan. It is a vital component of an effective HACCP food safety program.

Regulatory Basis for HACCP

In the United States, regulatory requirements for HACCP systems are codified in 9 CFR Part 417, which mandates that meat, poultry, and egg product processors develop and implement a written HACCP plan for each product type. This regulation is enforced by the USDA’s Food Safety and Inspection Service (FSIS) and requires facilities to conduct a hazard analysis and identify critical control points to ensure product safety and compliance.

The FDA also has regulatory requirements for HACCP, specifically for juice and seafood producers.

In some cases, HACCP training may be required. For example, SQF certification requires every site to have an SQF practitioner and substitute practitioner who have completed a HACCP training course.

Completing HACCP training is a great idea if your organization requires a HACCP food safety plan. This ensures your team understands the system as well as possible, which will help you develop a strong HACCP plan capable of meeting food safety certification requirements.

FSNS offers virtual (live, instructor-led) HACCP Training as well as Advanced HACCP Training for food safety professionals.

What is HACCP Certification?

While people often inquire about “HACCP certification”, a site does not obtain HACCP certification in a standalone audit.

Rather, review of a site’s HACCP plan may be part of a regulatory assessment, third-party GMP audit, or third-party GFSI audit. An individual person could choose to take a HACCP training course and obtain a certificate upon completion to indicate they have become “HACCP Certified”, but your site cannot achieve HACCP certification.

What are the Benefits of Implementing a HACCP Plan?

Maintaining the highest standards for food safety practices benefits not only your company, but your customers as well. These are a few benefits of implementing a HACCP plan that you can expect:

- Where applicable, meet regulatory requirements to produce products for distribution in interstate commerce.

- Adhering to internationally recognized HACCP food safety standards will help your company grow market share, increase business, and access new markets.

- Trusted, safe products coming from reputable companies inspire brand loyalty.

- When reviewing your facilities and procedures, you can find opportunities to increase efficiency, helping streamline production.

- Maintaining strict standards provides a service in bolstering public health as well as increased trust in your products.

- Your HACCP plan reduces risks to your employees, equipment, and customers.

- Wasted product and shrink are exponentially reduced.

- Implementing a good HACCP plan reduces the likelihood of customer complaints and costly recalls.

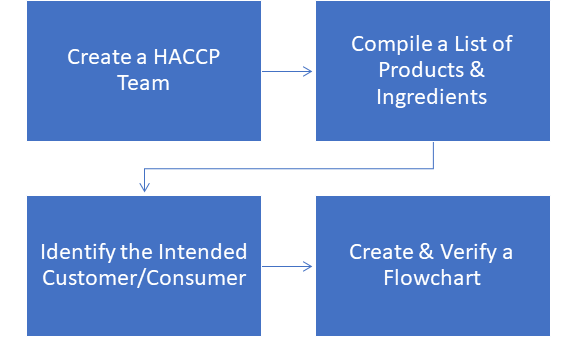

What are the Preliminary Tasks to Writing a HACCP Plan?

Now, let’s talk about how to make a HACCP plan.

There are several steps to writing an effective HACCP plan. Each must be carefully considered and thoroughly studied. Start with these preliminary tasks to help develop the best possible plan.

- Create a HACCP Team: When assembling and training your HACCP team, choosing the right people is essential. Ensure that the team is diverse in knowledge and experience, and that the team is reflective of the size and complexity of your company.

- Compile List of Products and Ingredients: Assemble a detailed list of all the products and ingredients (and sub ingredients) your company is, or will be, handling. This helps isolate high-risk substances that will need to be treated with care. In addition, identify how it will be packaged and the packaging materials that will be used.

- Identify Intended Customers/Consumers and Distribution: Keeping the intended user in mind can help your team consider what, if any, special steps or procedures are required, particularly for immunocompromised groups. It helps to visualize satisfied customers when assembling the plan that is intended to keep them safe. How will this product be shipped? Is there any food safety labeling required?

- Create and Verify a Flowchart: All inputs and outputs of the process should be included to allow for hazard evaluation. Beginning with the purchase of raw materials from a supplier, fully chart the progression of the production process, making note of key control process steps. This flowchart shall be verified by the HACCP team in real-time to ensure its accuracy to the process.

Completing these steps helps you execute a robust Hazard Analysis, which is the foundation of the development of your HACCP plan.

Check out our blog on 5 tips for successfully implementing your HACCP plan.

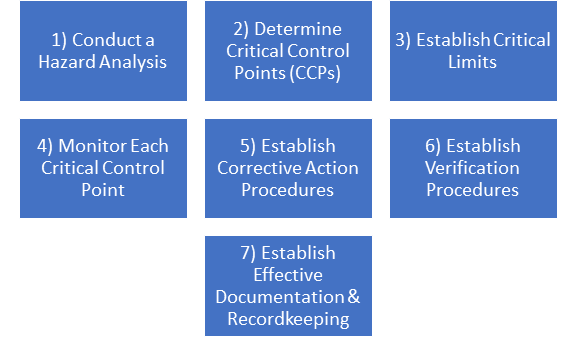

What are the 7 Principle Steps of HACCP?

There are 7 principle steps that must be taken when creating your HACCP plan:

- Conduct a hazard analysis

- Determine critical control points (CCPs)

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping and documentation procedures

Let’s look at each step more closely.

1) Conduct a Hazard Analysis

The first step in developing a HACCP plan is to conduct a hazard analysis.

- Gather and evaluate information about hazards exposed to food products to determine significant hazards to include in the HACCP plan.

- Conduct a thorough walkthrough and comprehensive study of raw materials, ingredients, and production processes.

- Consider unconventional risks, including surfaces, equipment, and placement of hazardous materials.

- Assess biological, chemical, and physical hazards posed to products.

- Identify significant hazards requiring control measures.

- Represent every ingredient and process step in the documented hazard analysis from the flow diagram.

- Describe in the HACCP plan the potential hazard, its severity, and likelihood of occurrence in products and processes.

- Demonstrate complete understanding of production processes and potential hazard points in developing a HACCP plan.

- Include all steps from accepting raw materials to packaging finished products.

- Involve a diverse cross-section of organizational personnel in the HACCP team for a comprehensive grasp of each process step.

- Ensure successful hazard analysis through inclusive team representation.

2) Determine the Critical Control Points (CCPs)

What is a critical control point in HACCP? It is a step in your production process at which control can be applied to help prevent, eliminate, or reduce to an acceptable level a significant food safety hazard.

Once you understand the definition, it’s time to identify the CCPs in your HACCP plan. The critical control points must address the potential hazards that are reasonably likely to cause injury or illness in their absence. This is where expert knowledge is indispensable, which underscores the need to assemble an expert HACCP team.

Identify any step in the production process where hazards can be prevented, eliminated, or reduced to acceptable levels as a critical control point. Examples of CCPs include the following:

- Cooking

- Chilling

- Cold storage

- Hot holding

- Product formulation

Heating a product to a specified temperature for a specified minimum time to kill microorganisms could be a critical control point. Similarly, refrigeration to prevent microbial growth could be another critical control point. The CCPs will vary depending on the food you are producing, and they can even vary between facilities that produce the same food.

Ensure that your HACCP team carefully documents each critical control point in your HACCP plan. Depending on your regulatory agency, establish your critical control points using USDA-FSIS HACCP guidelines or FDA (Fruit/Vegetable Juice, Seafood) HACCP guidelines.

3) Establish Critical Limits for Each Critical Control Point (CCP)

According to NACMCF, a critical limit in a HACCP program is the maximum and/or minimum value to which a biological, chemical, or physical parameter must be controlled at a CCP to prevent, eliminate, or reduce to an acceptable level the occurrence of a food safety hazard.

Move through the list of CCPs and establish specific, detailed critical limits that scientifically control the identified hazards.

For example, if your company processes and uses raw chicken, your critical control point may include cooking the chicken to eliminate significant hazards such as Salmonella. The critical limit for that CCP may be 165ºF internal product temperature, derived from published scientific literature.

4) Monitor each Critical Control Point

Once the CCPs and critical limits are established, follow through. Monitoring (identifying the What, How, When, and Who) ensure your critical limits are being met.

Critical limits are ideally measurable and observable. Preferably, it should be possible to monitor critical limits continuously via physical or chemical methods, such as monitoring the temperature of food products using calibrated equipment.

Any deviation could result in foodborne illness and harm to customers, which underscores the importance of effective monitoring of critical limits.

Personnel assigned to monitor critical limits should be properly trained and demonstrate an understanding of the process, including what to do in the event of a deviation.

5) Establish Corrective Action Procedures

Corrective actions are the responses taken when critical limits or monitoring procedures are not met. Corrective actions should include the following:

- Identify and correct the deviation; get the CCP back in control.

- Investigate the root cause of the deviation and implement preventive measures.

- Evaluate the product disposition.

- Record the corrective actions taken.

Corrective actions should be conducted, where appropriate, to the regulatory requirements for correcting deviations of CCPs. Additionally, develop corrective actions for each critical limit in advance and document them as a training mechanism for personnel involved as a preparation activity. At minimum, include actions to be taken when a deviation occurs, the person in charge, and the information to be documented.

Defining corrective actions in advance – like longer cooking times or discarding food that doesn’t meet the proper temperature – helps employees know what to do in certain situations.

6) Establish Verification Procedures

This is arguably the most important part of your HACCP plan.

Verification procedures are the activities, not counting monitoring, that answer the question, “Are we doing what we said we were going to do?” Verification activities may be related to verifying the totality of the HACCP system, or verification activities for each individual CCP.

This can include frequent review of your HACCP plan, verification that it is being followed, and review of critical control points and critical limits. Examples of verification activities for CCPs may include the following:

- Calibration of monitoring device

- Direct observation (FSIS)

- Record review

- Pre-shipment review (FSIS)

- CCP adequacy review

It is also a good idea to consult a qualified third-party organization, such as EAS Consulting Group, to verify your HAACP plan procedures, for example through internal audits or gap assessments. This can uncover potential problems your team may have missed and provide independent information that helps you develop a robust and effective HACCP food safety system.

Your plan can be re-worked accordingly based on the performance and results of verification activities.

7) Establish Effective Documentation and Recordkeeping

“If it was not written down, it did not happen.” Records are the evidence of your HACCP plan.

Use your data to help you understand if your HACCP plan is working as intended. Documented evidence may be a combination of documents (developed programs, Standard Operating Procedures, Good Manufacturing Practices, policies, work instructions) as well as real-time records (data documented into/onto paper or digital forms). Records may include the following:

- HACCP team members and their responsibilities

- Description of the food, its distribution, intended use, and target consumer

- Flowchart

- Hazard analysis summary, including rationale for a decision

- Critical control points

- Critical limits

- Corrective actions

- Verification procedures and schedule

- Any support documents such as scientific studies

- Prerequisite programs

- Realtime Authentic HACCP and operational records

Which Special Process Requires a HACCP Plan?

Some facilities may prepare or preserve food using non-thermal methods, such as brining or curing. Some special processes require a HACCP plan and/or variance to be used at your facility. The information contained in your plan is the same as for non-special processes covered above.

Some examples of special processes that require a HACCP plan include the following:

- Curing through use of nitrites or nitrates

- Using vinegar to preserve fruit or vegetables

- Reduced oxygen packaging

- Smoking meat, fish, or other food

- Curing meat or other food

- Acidification

- Using a live holding tank for shellfish

Check your local regulations for guidance.

Is HACCP a Codified System?

Yes, HACCP is a codified system in that it is located in the Code of Federal Regulations:

- USDA: Title 9 Part 416 and 417

- FDA: Title 21 Part 120 for juice, Part 123 for fish and fishery products

9 CFR Part 417 requires establishments to conduct a hazard analysis and develop a written HACCP plan that covers each product produced to promote food safety.

21 CFR Part 120 mandates that any processor of juice sold as such or used as an ingredient implement a HACCP plan, while Part 123 outlines the same requirements for processors of fish and fishery products.

Prepare Your Team With HACCP Training

Since its adoption in the 1990s, HACCP has marked a significant advance in food safety management. However, knowing how to make a HACCP plan for your facility can be complex. Whether you’re developing a plan to meet regulatory obligations or to enhance food safety voluntarily, completing a HACCP training course equips your team with the knowledge and skills to write an effective and comprehensive HACCP plan.

FSNS offers in-person and online HACCP training courses throughout the year at locations around the United States. Our instructors offer decades of experience in food safety to help prepare you for success.

Our labs provide a full range of food safety testing to support your safety program.

HACCP FAQs

HACCP (Hazard Analysis and Critical Control Points) is an internationally recognized systematic method of identifying, managing, and controlling significant hazards associated with the manufacture of food, including biological, chemical, and physical.

HACCP stands for Hazard Analysis and Critical Control Points. It is a systematic, science-based approach to identifying, evaluating, and controlling hazards that can affect food safety throughout the supply chain.

The purpose of HACCP is to prevent food safety hazards before they occur by identifying potential risks and implementing control measures at critical points in the production process. This proactive system helps ensure safe food handling, protect public health, and support regulatory and industry compliance.

The seven principles of HACCP are:

1. Conduct a hazard analysis

2. Determine critical control points (CCPs)

3. Establish critical limits

4. Establish monitoring procedures

5. Establish corrective actions

6. Establish verification procedures

7. Establish record-keeping and documentation procedures

These steps form the foundation of a robust food safety plan.

HACCP is used by food manufacturers, processors, distributors, and service providers across the entire food industry. It is especially important in high-risk sectors like meat, poultry, seafood, dairy, and ready-to-eat foods, but it is applicable to any organization involved in food production or handling.

In the United States, HACCP is legally required for certain sectors such as meat and poultry (regulated by USDA), seafood and juice (regulated by FDA). While not mandatory for all food businesses, HACCP is widely adopted as a best practice and is often required by major retailers, foodservice providers, and global food safety certification programs.