As a food manufacturer, you need to do more than develop great-tasting products on schedule and within your budget. You must go the extra mile to ensure your food products are high-quality and safe for consumption.

Furthermore, you should confirm that your facility complies with your regulations, but also, to be competitive, higher food safety and quality standards.

The good news is there’s one thing you can do to tick all the boxes: obtain SQF certification.

SQF certification demonstrates that you are committed to fostering a rigorous food safety management system at your facility. This enables you to protect your customers, reduce the chances of a recall, and safeguard your brand.

SQF Meaning Explained

What does SQF stand for? SQF is an acronym for “Safe Quality Food”.

Overseen by the Safe Quality Food Institute, SQF is a global food safety program whose goal is to ensure food safety.

It is based on Hazard Analysis Critical Control Points (HACCP) and is recognized by the Global Food Safety Initiative (GFSI). Many retailers and manufacturers worldwide require SQF certification before purchasing food products from companies like yours.

What is SQF Certification?

That raises the next question: What is SQF certification?

SQF certification is an independent, third-party validation that your product, process, or service complies with the standards outlined in the SQF code (currently SQF edition 9).

This provides you with several benefits, including…

- Establishment of a robust food safety control system.

- Assurance for retailers and other distributors that your products have been produced and prepared according to globally recognized standards.

- Access to top retailers, helping you expand your sales.

- Decreased risk.

- Stronger brand image.

What are the Different SQF Programs?

To get started on your way to SQF certification, you first need to select the appropriate food safety program.

The Safe Quality Food Institute offers 5 different SQF programs from which to choose for your facility. This offers the flexibility to use the program that best fits your company’s size and needs.

Here’s a glance at them:

| Program | Who’s It For? | Prerequisites | GFSI-Benchmarked? |

| Food Safety Program | All food producers | None | Yes |

| Fundamentals Program | Small & medium companies | None | Yes |

| Quality Program | Sites with robust food safety plans | SQF food safety plan or similar | Yes |

| Foodservice Program | Foodservice businesses | None | No |

| Food Retail Program | Food retailers | None | No |

How Much Does SQF Certification Cost?

Total SQF certification cost will depend on the steps your facility must take to ensure your product, processes, or service comply with the standards defined in the SQF code. Some facilities have food safety programs in place and may be ready to pass an SQF audit today. Other facilities may require quite a bit of work before being able to pass an audit.

No matter where your facility falls on the spectrum, you need to schedule and pass an SQF audit from a licensed certification body, such as FSNS Certification & Audit. A 2-day audit from FSNS C&A costs under $6,000.

View it as an investment in your facility’s food safety program and quality goals. Certification is also required to access many retailers, which helps you recoup the cost of the SQF audit and boost revenue.

How Do I Get SQF Certified?

You’ve chosen an SQF food safety program. Now, what?

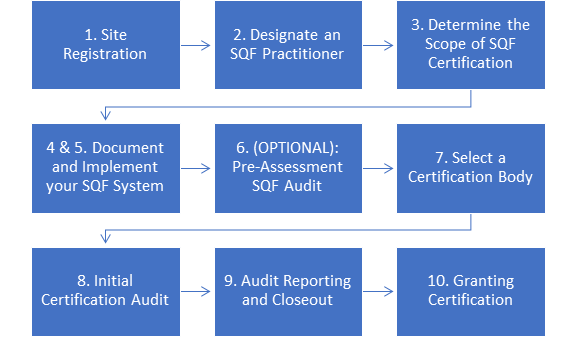

Since an SQF certification involves the public’s health and safety, the process of earning it is deliberately designed to be robust and meticulous. It includes the education, implementation, auditing, and maintaining of safety standards within your facilities.

Here is a simple outline of the steps you will need to take to earn SQF certification.

STEP 1: Site Registration

To be considered for SQF certification, register your facility on the SQFI assessment database. Note that there is a fee for registration and annual renewals. You need to register your site with SQFI prior to the start of the initial certification audit.

STEP 2: Designate an SQF Practitioner

Appoint a full-time employee to act as your SQF practitioner. This person will need to complete a HACCP-based training course and, ultimately, gain a working knowledge of SQF code, and meet the requirements outlined below.

You need to designate a primary and substitute practitioner who meet the following requirements:

- Must be employed by your site.

- Hold a position of responsibility to managing an SQF program.

- Have completed a HACCP/PCQI training course.

- Be competent to implement and maintain HACCP-based plans.

- Understand the SQF code (FSNS offers an SQF practitioner training course).

You may have more than one SQF practitioner within your team so you can efficiently oversee the development and implementation of the SQF food safety program in your facility. Having a “substitute” at minimum is required.

STEP 3: Determine the Scope of SQF Certification

Next, you must determine the scope of certification for your SQF audit, meaning the food sector categories, products, and processes that will be included in your system.

The scope determines what elements of the SQF code are applicable to your SQF certification. There are several Food Sector Categories to review to determine where your products fit, such as for egg processing; dairy food processing; slaughtering, boning, and butchering; and more.

Once you identify your Food Sector Categories, you will be responsible for implementing the system elements and your relevant GMP module based upon your scope.

STEPS 4 and 5: Document and Implement your SQF System

This step requires the most time and resources. It requires documenting and implementing the requirements of the SQF code and developing your own SQF system.

Programs, policies, procedures, work instructions, and specifications need to be developed and implemented to meet the requirements of the SQF code.

Here a just a few examples of what must be implemented in your SQF food safety program:

- Records of all investigations, root cause analyses, and resolution of non-conformities, their corrections, and the implementation.

- Annual review and validation of critical food safety limits.

- Cleaning and sanitation activities and records.

- Proper handling and storage of food.

- Internal audits and inspections.

Our auditors documented the top 10 reasons they find for SQF audit non-conformities here. Review the list to understand the common areas where facilities come up short.

STEP 6 (OPTIONAL): Pre-Assessment SQF Audit

A pre-assessment SQF audit is not required but is an excellent way to determine if your facility is on the right track before completing the certification audit. There may be onsite and remote review of your SQF system to help identify gaps in your implementation.

Contact FSNS Certification & Audit to schedule a pre-assessment SQF audit.

STEP 7: Select a Certification Body

Certification Bodies (CBs) are licensed by SQFI to conduct SQF audits and issue certificates. These CBs are accredited to the international standard ISO/IEC 17065:2012 (or subsequent versions). All SQF CBs are held to standards and annual assessments to meet requirements for SQFI.

Once selected, you and the CB will begin the set up to schedule your SQF audit, including confirming scope and required SQF code sections with your FSC.

STEP 8: Initial SQF Audit

A qualified and registered food safety auditor (or team) will check that your documentation meets the SQF code and that your activities are conducted according to your documented policies, procedures, and specifications.

Download our SQF Audit Checklists to help prepare for your audit. We have two checklists available, depending on your Food Sector Category:

SQF Audit Checklist for Food Sector Categories 10-22, 25, & 33

SQF Audit Checklist for Food Sector Categories 7-9

STEP 9: Audit Reporting and Closeout

The auditor(s) gather evidence of compliance or non-compliance with the appropriate SQF code by reviewing documentation, interviewing staff, observing operations, and other tactics. You are given a score in your audit report based on the findings.

STEP 10: Granting SQF Certification

The Certification Body will determine based on evidence gathered during its SQF audit whether you receive certification or not. If your site meets requirements, you will receive a copy of your site’s certification within 10 days.

How Long Does it Take to Get SQF certified?

The audit duration is no less than two days, including document reviews and facility assessments. However, the whole process of having your site evaluated for SQF certification can take anywhere from 6 months to a year or more.

Here are some of the factors that can speed up or slow down your SQF certification process:

- Existing certifications.

- Correct implementation and documentation from proper training.

- The scope of the audit.

- The number and complexity of processes to be assessed.

- The ease of communication with on-site personnel.

Questions about SQF Audits or Certification?

We understand that an SQF audit and certification is crucial to your success, and we’re here to help make the process more efficient for you.

FSNS Certification & Audit (FSNS C&A) is an independent and accredited entity offering nationwide and international certification and audit services. Through our objective assessment process, we ensure that your site meets global standards and stays ahead of the competition.

Contact FSNS C&A if you need help securing an SQF certification for your facility.