For those in the food industry, the successful implementation of HACCP (Hazard Analysis and Critical Control Points) is paramount to ensure the safety and quality of food products.

HACCP’s systematic approach, from raw material procurement to consumption, is internationally recognized as an effective way to prevent food contamination and ensure consumer safety. However, navigating the complexities of HACCP implementation can be daunting.

From dedicated personnel and comprehensive planning to the necessary infrastructure and continuous training, every aspect presents a unique challenge. As with any significant undertaking, a weak link in the chain can lead to failure.

This guide explores common obstacles to successful implementation of HACCP and how you can overcome them.

Challenges to Successful Implementation of HACCP

1. Incomplete or Inaccurate Hazard Analysis

Identifying all potential hazards and critical control points, accurately assessing their severity and likelihood of occurrence, and correctly developing the HACCP flow diagram are challenging aspects of HACCP implementation that can lead to inadequate control measures.

Shortcuts in these steps may result in missing hazard identifications, thereby compromising the HACCP plan’s effectiveness.

Strategies for Successful HACCP Implementation:

- Comprehensive Expertise: Assign individuals knowledgeable about HACCP principles and the food manufacturing process to conduct the hazard analysis. They should be able to discern “critical” contamination points and establish specific controls to prevent or reduce risks.

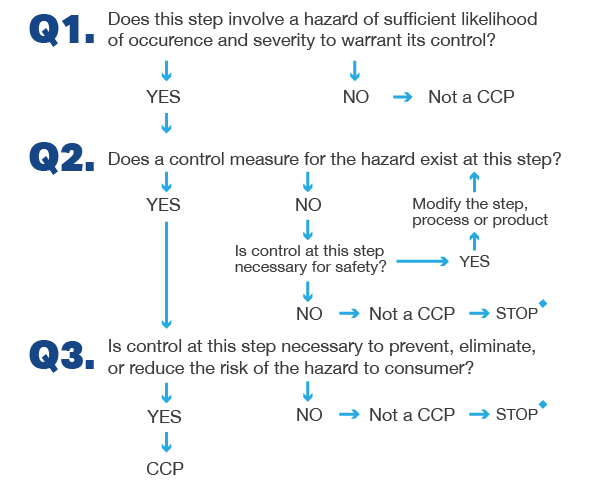

- Use a Decision Tree: To better determine critical control points, use a decision tree to visualize the sequence of events where risks can occur. FDA has a helpful HACCP decision tree example on its website here.

- Develop Prerequisite Programs: Develop programs like Sanitation Standard Operating Procedures (SSOPs) and Good Manufacturing Practices (GMPs) to minimize the likelihood of hazards and contamination risks.

- Robust Supplier Approval Program: Implement a strong supplier approval program to evaluate your suppliers’ HACCP practices. Regularly conduct audits to verify the safety and quality of incoming materials.

- Documentation and Assessment: Ensure accurate documentation during the hazard analysis phase. It’s a crucial step to the successful implementation of HACCP at your facility.

2. Lack of Employee Training

Without proper employee HACCP training, successful HACCP implementation may be compromised. Employees need to understand HACCP principles and the significance of identifying problems proactively.

Solutions

- Regular Training: Establish regular training programs to ensure all employees understand HACCP principles and how to execute an effective food safety management system.

- Monitoring: Individuals tasked with monitoring should be adequately trained, unbiased, and accurate in their reporting. They should also be trained in procedures to address any trend toward loss of control.

- Meticulous Records: Keep detailed training records for inspection and outbreak investigation purposes.

- Fostering a Food Safety Culture: Cultivate a culture of food safety across all levels of the organization to ensure successful HACCP implementation.

3. Insufficient Documentation

Lack of adequate documentation can lead to inconsistent practices, difficulty in tracking efforts, and evaluating the effectiveness of critical control points. From a regulatory perspective, if it isn’t documented, it didn’t happen.

Solutions

- Clear Procedures: Establish clear and standardized procedures for documenting HACCP plans, monitoring records, and corrective actions. These records should also include employee training programs.

- Regular Reviews: Conduct regular reviews of documented procedures and collected data to ensure accuracy, relevance, and trend identification.

- Detailed Recordkeeping: Keep detailed daily records and CCP monitoring records to ensure you meet regulatory requirements and enhance food safety.

4. Limited Resources and Time Constraints

The successful implementation of HACCP requires substantial resources, including time, personnel, and finances. Many companies struggle to allocate these resources adequately, resulting in insufficient HACCP implementation.

Solutions

- Cost Evaluation: Consider both direct and indirect costs associated with HACCP implementation. Costs may include training, hazard analysis, equipment upgrades, and changes in production lines or workspaces.

- Long-term Investment: See HACCP plan development as a long-term investment. It can prevent costly foodborne illnesses, reduce product recalls, enhance customer trust, and ensure regulatory compliance.

- Collaborations and Outsourcing: Collaborate with regulatory bodies, industry associations, and consultants to overcome resource constraints. Consider outsourcing certain processes like validation testing to ease in-house testing costs and challenges.

5. Lack of Continuous Monitoring and Verification

HACCP implementation requires constant monitoring and verification to remain effective. The plan must be reassessed at least annually and whenever changes occur that could affect the hazard analysis or alter the HACCP plan.

Solutions

- Regular Audits: Conduct regular audits, inspections, and internal reviews to assess the effectiveness of HACCP systems. Implement feedback and corrective actions promptly based on monitoring results.

- Timely Testing: While microbiological testing may provide crucial data, more immediate feedback can be obtained through monitoring CCPs via physical and chemical tests like temperature, time, pH, and moisture level measurements.

- HACCP Plan Review: Whenever there is a change in the product, process, or equipment, the HACCP plan should be reviewed. The plan should also be reviewed in case of incidents related to food safety, such as illnesses, product recalls, or customer complaints.

- Stay Updated: Keep abreast of changes in regulatory requirements or industry standards. Incorporate any changes into the HACCP plan to ensure ongoing adherence to the latest guidelines and regulations.

Expert Help for Successful HACCP Implementation

While the successful implementation of HACCP is challenging, the rewards far outweigh the hurdles. It’s not just about compliance but about contributing to a safer food industry.

For those seeking to enhance their HACCP implementation strategies, EAS Consulting Group, A Certified Group Company, offers thorough HACCP audits and expert consulting.

Looking to bolster your team’s HACCP knowledge? Food Safety Net Services (FSNS) offers comprehensive HACCP education and training to ensure you stay ahead of the curve. Our experts can help you turn challenges into stepping stones for success. Get in touch today.