Aaron Pleitner

Aaron Pleitner

Aaron Pleitner

Aaron Pleitner

1-Minute Summary

- Traditional methods give low-cost, qualitative insight into airborne fallout – ideal for trending and setting baselines.

- Device-aided traditional methods provide quantitative data for high-care areas, including both airborne and compressed-air testing.

- Using both strengthens your EMP with routine trending, quantitative verification, and fast investigative response.

Choosing the Right Air Sampling Method for Your Food Plant

Air is one of the least considered pathways for microbial contamination in food manufacturing, even though it can transport yeast, mold spores, and airborne bacteria throughout a facility, increasing the potential for spoilage in finished product. Most QA teams already know they need air sampling as part of their environmental monitoring program and to meet requirements from SQF, BRCGS, and customer standards. What often needs clarity is how to perform air sampling in food manufacturing environments and which methods fit which needs.

Food plants typically rely on two categories of air sampling technologies, each suited to monitoring different risks and operational scenarios:

- Traditional Methods (settle plates): for routine monitoring of airborne fallout.

- Device-Aided Traditional Methods (AES active air sampling, CAMTU compressed-air testing): for quantitative data or compressed-air applications.

This guide compares both methods, explains how they complement one another, and outlines how they fit into a risk-based EMP.

Traditional Methods: Simple, Low-Cost Air Sampling for Routine Monitoring

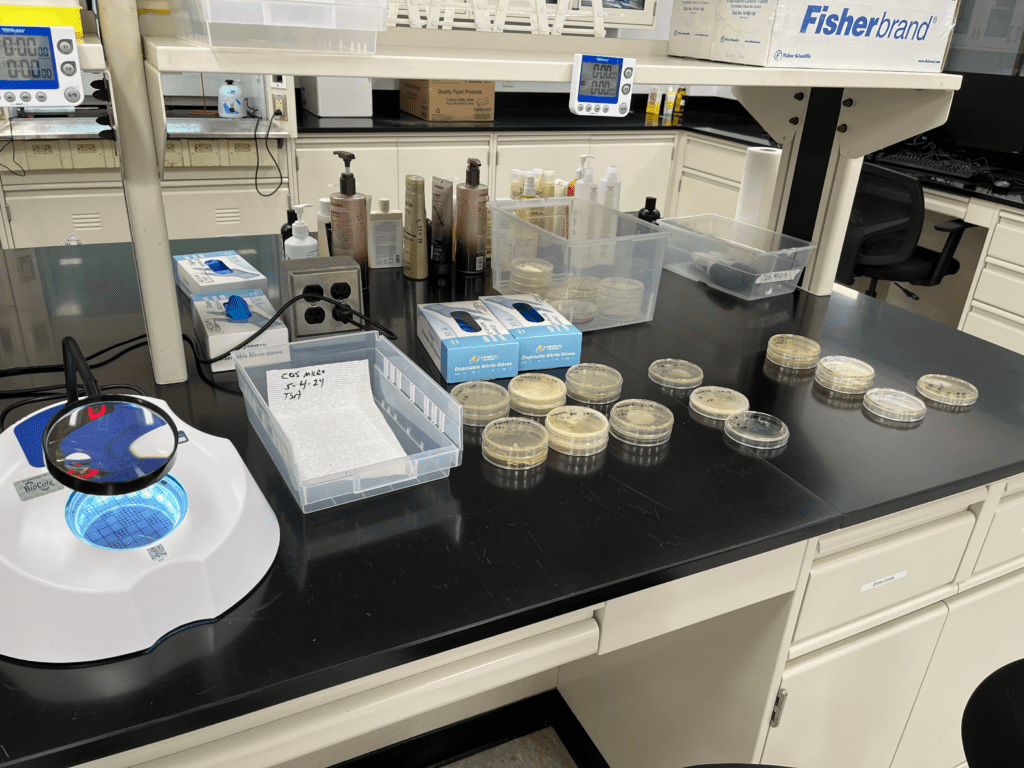

Traditional air sampling relies on settle plates, or passive air sampling, to capture airborne microorganisms that naturally fall out of the environment. This method remains widely used in air sampling in food manufacturing because it is inexpensive, easy to perform, and accepted across major certification schemes.

Though not quantitative, settle plates provide a practical snapshot of airborne fallout – especially useful for tracking yeast and mold.

How Traditional Methods Work

Settle plates use standard agar media (e.g., PDA/SDA for yeast and mold, TSA for APC). Plates are left exposed for 15–30 minutes, allowing airborne particles to settle by gravity. After incubation, colonies reveal the level of fallout in that area.

Because yeast and mold spores are lightweight and easily airborne, settle plates are particularly good at detecting them during routine air monitoring in food production environments.

Strengths of Traditional Passive Air Sampling

Traditional methods remain a staple of many environmental monitoring programs because they offer meaningful information with minimal effort.

Key advantages include:

- Low cost for routine or high-frequency trending.

- No specialized equipment required.

- Easy to train and implement.

- Accepted across SQF, BRCGS, and customer audits.

- Useful for general environmental hygiene checks or identifying areas to evaluate further with device-aided methods.

Limitations of Traditional Methods

- Not quantitative – results reflect passive collected fallout, not CFU/m3.

- Influenced by air movement such as fans, doors opening, or personnel flow.

- Less reliable for heavier bacterial indicators (APC, coliforms).

- Longer turnaround times (5–7 day incubation time for yeast and mold).

- Difficult to compare across rooms or facilities.

These limitations make traditional methods best suited for baseline trending of dedicated areas of facilities.

When Traditional Methods Are the Best Choice

Settle plates are ideal for routine, low-cost monitoring of airborne fallout and for supplementing quantitative methods.

They are most useful for:

- Routine trending in general production areas.

- Baseline monitoring when setting facility action limits.

- Verifying sanitation practices over time.

- Monitoring yeast and mold activity, especially in bakery, beverage, produce, and dairy environments.

- Supporting an EMP without requiring expensive equipment.

Device-Aided Traditional Methods: Quantitative Air and Compressed Air Testing

Device-aided traditional methods play a central role in air sampling in food manufacturing, especially when plants need quantitative, volume-controlled data or when compressed air is used as a processing aid or as part of unit operation. These technologies do not replace settle plates but build on them, giving QA teams precise, defensible measurements for high-care, high-risk, or compressed-air applications.

This category includes two common technologies:

- Active air samplers (AES Air Sampler Lite)

- Compressed-air microbial testing (CAMTU)

Both are essential for a modern, risk-based EMP, but they serve different purposes.

Active Air Samplers (AES Air Sampler Lite)

Active air samplers pull a defined volume of air across an agar plate using a perforated impaction head. This controlled airflow allows for quantitative results, which are especially valuable in high-care or ready-to-eat (RTE) environments.

Strengths of Active Air Sampling

Active air samplers provide the level of accuracy and repeatability that auditors and corporate quality teams expect for airborne environmental monitoring.

Benefits include:

- Quantitative data (CFU/m³) for actionable trending.

- High sensitivity, especially for APC and coliform bacteria.

- Strong audit alignment with SQF, BRCGS, and customer standards.

- Consistent sampling volume, making results comparable across rooms, days, and facilities.

- Ideal for high-care/RTE zones where airborne contamination poses greater risk.

- Excellent for verifying HVAC performance, filtration, and pressure differentials.

By controlling the volume of air pulled across the agar, active air samplers overcome the variability inherent in passive settle plates.

Limitations of Active Air Sampling

Despite their accuracy, active samplers have limitations:

- Equipment cost and maintenance, including routine calibration.

- Requires proper operator training for consistent results.

- Turnaround time is still dependent on incubation time, typically 48 hours for APC and 5–7 days for yeast & mold.

- Less practical for wide-area, high-frequency monitoring due to equipment handling.

These considerations make AES units most appropriate when precise, defensible data is required.

Best Uses for Active Air Samplers

Active air sampling is ideal for:

- RTE and high-care areas.

- Facilities needing quantitative airborne data.

- Audit preparation.

- Investigating elevated APC, coliform, or yeast & mold counts.

- Evaluating HVAC airflow or filtration performance.

In short, active sampling is the gold standard for air sampling in food manufacturing when quantitative, repeatable airborne data is required.

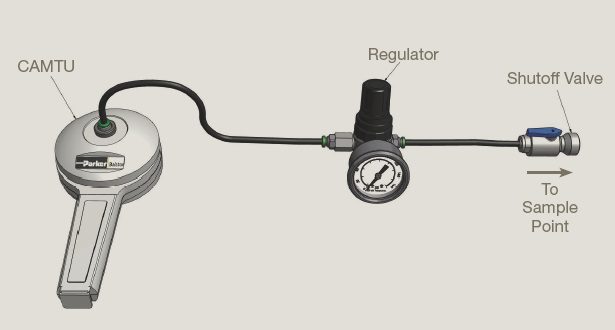

Compressed Air Testing (CAMTU)

When compressed air interacts with food, it becomes a direct food-contact risk. CAMTU testing (Compressed Air Microbial Testing Unit) assesses the microbial quality of compressed air used for:

- Air knives

- Blow-offs

- Packaging lines

- Pneumatic systems

- Product movement

CAMTU units direct a controlled stream of compressed air onto an agar plate or hydrated sponges, allowing a facility to evaluate both microbial contamination and moisture within the air system.

Strengths of CAMTU Testing

Compressed air is a known source of contamination in both wet and dry facilities. CAMTU testing is essential for:

- Detecting microbial contamination inside compressed air lines and on exit ports.

- Identifying moisture problems that promote microbial growth.

- Evaluating air used in direct or indirect food contact situations.

- Meeting auditor expectations – most GFSI schemes expect compressed-air quality verification.

It is one of the only reliable ways to assess whether compressed air is clean and safe for use near product, packaging, or post-lethality processes.

Limitations of CAMTU Testing

- Only applicable where compressed air contacts or influences product.

- Still dependent on culture incubation times.

- Does not quantify general airborne microbial loads.

Because of these constraints, CAMTU should be used alongside – not instead of – active and passive air monitoring.

Best Uses for CAMTU Testing

CAMTU compressed-air microbial testing is ideal for:

- Any system where compressed air reaches food or food-contact surfaces.

- Quarterly or annual audit compliance checks.

- Identifying moisture issues within and upon exit of compressed air lines.

- Supporting root-cause analysis for unexpected environmental positives.

Together with active and passive air testing, CAMTU completes the air-quality picture for a food manufacturing environment.

Comparison of Air Sampling Methods for Food Manufacturing Environments

Selecting the right approach to air sampling in food manufacturing environments depends on the level of precision you need, the organisms of interest, and cost. The table summarizes the key differences at a glance, followed by a brief explanation of how to interpret the results.

Comparison Table: Air Sampling Methods Used in Food Plants

| Category | Sampling Time | Sensitivity/Ability to Quantify | Result Type | TAT | Cost |

| Traditional (Settle Plates) | 15–30 minutes exposure | ✓ (lower sensitivity; best for airborne fallout) | Qualitative (fallout only; not CFU/m³) | 5–7 days | ✓ |

| Device-Aided Traditional (AES, CAMTU) | 5–10 minutes | ✓✓ (volume-controlled, higher sensitivity) | Quantitative (CFU/m³ or compressed-air evaluation) | 5–7 days | ✓✓ |

Choosing the Right Air Sampling Method

By this point, most facilities know what they need from an air-monitoring program. The decision usually comes down to how precise the data must be, overall cost, and where the sampling will occur. Here’s the simplest way to choose:

Use Traditional (Settle Plates) when:

- You need low-cost, routine trending.

- You’re monitoring general production areas for yeast and mold fallout.

- You want basic environmental hygiene insight without equipment investment.

Use Device-Aided Traditional (AES, CAMTU) when:

- You need quantitative results (CFU/m³) for audits or corporate standards.

- You’re monitoring RTE or high-care environments.

- You must verify compressed air used on packaging or product-contact surfaces.

- You need higher sensitivity for APC, coliforms, or broader indicators.

In practice, most food manufacturers use a combination of all both. Traditional methods handle routine trending and device-aided sampling provides quantitative accuracy.

How Our Lab Supports Air Sampling Programs

Our food testing labs supply and support both of these air-sampling technologies used in food manufacturing, including:

- AES Air Sampler Lite rental units.

- CAMTU rental units and consumable supplies.

- Media and supplies for traditional settle plates.

- Lab testing for yeast & mold, osmophilic yeast & mold, APC, coliforms, and other organisms with validated methods, ISO 17025 accreditation, and competitive turnaround times.

Contact our Customer Service Team if you need air sampling for your food manufacturing facility. Whether you’re launching an air-sampling program or strengthening an existing EMP, our specialists can help you design the right approach, interpret results, and prepare for audits.