Reviewed and Approved by Dr. Keith Belk, Professor & Monfort Endowed Chair, Colorado State University

1-Minute Summary

- Biological hazards in food, including bacteria and the toxins they produce, viruses, fungi, and parasites, can cause severe health complications.

- Biofilms resist sanitizing, enhancing the ability of pathogens to contaminate food products.

- Food Safety Management Systems like HACCP are essential for monitoring and controlling food safety hazards.

- Regular testing methods are crucial for identifying biological hazards in food.

- Training, audits, and strong traceability systems are key to mitigating biological food safety risks.

While food is a vital source of the energy and nutrients our bodies require, it can sometimes pose a risk to our health due to the presence of hazards. The types of hazards that threaten food safety generally fall into three categories:

- Chemical

- Physical

- Biological

This blog post will delve into understanding biological food hazards, providing detailed examples, and exploring preventive measures, particularly for food manufacturing and processing companies.

What is a Biological Hazard in Food?

Biological food hazards are living organisms or substances produced by these organisms that pose a threat to human health.

They are among the most common causes of foodborne illnesses and can result in severe health complications. The dangers of consuming food contaminated with biological hazards can range from mild stomach pain to life-threatening conditions like kidney failure or even death.

What is a Biological Hazard in Food Example?

Biological hazards in food are categorized into four main types:

- Bacteria and their toxins

- Viruses

- Parasites

- Fungi

Each category represents a different kind of threat and requires a unique approach for prevention and control. To understand what an example of a biological hazard in food looks like, we’ll explore each category in more detail.

Bacterial Hazards in Food

Bacterial hazards pose one of the most significant risks to food safety. Pathogenic bacteria such as Salmonella, Listeria, and E. coli can multiply rapidly under certain conditions, namely warm temperatures and ample nutrients.

For instance, Salmonella can contaminate a wide range of food products, including poultry, eggs, and even fruits and vegetables. E. coli is often associated with contaminated ground beef but can also be found in produce, raw milk, and untreated water. Listeria, while less common, has a fair higher mortality rate associated with it and can grow even under refrigeration, making it a notable concern in ready-to-eat foods.

Biofilms and their Role in Biological Food Hazards

When discussing bacterial hazards, we need to mention a sanitation issue that is of considerable concern to food safety professionals: biofilms.

Biofilms are organized communities of microorganisms. Microbes within a biofilm produce a protective matrix that enables them to survive in harsh conditions and resist cleaning and disinfection efforts. Pathogenic bacteria like Listeria monocytogenes and Salmonella are known to form biofilms on a variety of surfaces in food processing environments, enhancing their ability to contaminate food products.

Controlling biofilms involves stringent cleaning and sanitation protocols. Use of surfactants and enzymes, proper sanitizers, and mechanical action can help disrupt biofilms. Furthermore, innovative strategies such as antimicrobial coatings and bacteriophages are being explored for biofilm control.

Viral Hazards

Viral hazards, while not able to grow in food, can still be transmitted through food and cause foodborne illnesses.

Norovirus, often linked to raw or inadequately cooked shellfish and contaminated water, is the most common causes of foodborne illness.

Hepatitis A, another significant viral hazard, can be associated with many types of food, including berries, shellfish, and raw produce, and is often a result of contamination from infected food handlers.

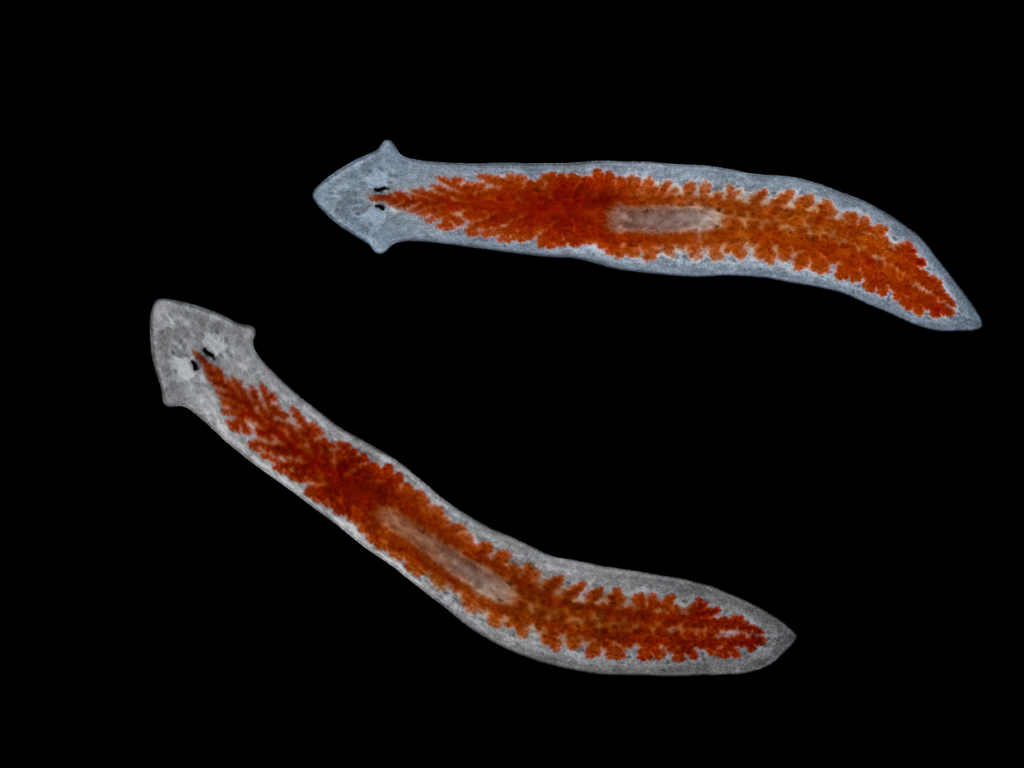

Parasitic Hazards

Parasites in food, though less common than bacterial or viral hazards, can lead to severe health conditions.

Tapeworms, for example, can be present in raw or undercooked fish, pork, and beef and can cause infections in humans when consumed.

Giardia, a microscopic parasite, can contaminate water and any food washed or irrigated with that water. These parasites can survive in the environment for long periods and can cause gastrointestinal illnesses with long-lasting symptoms.

Fungal Hazards

Fungi, including molds and yeasts, can spoil food and sometimes produce harmful toxins. Aspergillus, for instance, can contaminate crops like peanuts, corn, and cottonseed, producing aflatoxins, which are harmful, even at low concentrations.

Other molds, such as those from the Penicillium or Fusarium genera, can produce mycotoxins in grains and fruits under certain conditions. These mycotoxins can lead to serious health effects, including immune system suppression and cancer.

Toxins

Toxins produced by certain bacteria and fungi pose a significant risk because they can cause illness even if the producing organism is no longer present.

Botulinum toxin, produced by Clostridium botulinum, is one of the most potent neurotoxins known and can lead to botulism, a severe and potentially fatal illness.

Staphylococcal enterotoxins, produced by some strains of Staphylococcus aureus, can cause food poisoning with rapid onset. Unlike many bacteria, the toxins produced by these organisms are resistant to heat and cannot be destroyed by cooking.

Infamous Outbreaks Due to Biological Food Hazards

Historical instances of biological hazard outbreaks underscore the importance of stringent food safety measures. These outbreaks often lead to a significant number of illnesses, hospitalizations, and sadly, even deaths. Here are a few examples:

- E. coli Outbreak Linked to Slivered Onions (2024): In one significant outbreak, contaminated onions caused a widespread outbreak of E. coli O157:H7 infections across the United States. According to the FDA, this outbreak resulted in 104 illnesses across 14 states, leading to 34 hospitalizations and one death.

- Salmonella Outbreak Linked to Raw Turkey Products (2018-2019): Another example is a Salmonella outbreak associated with raw turkey products. This instance spanned across multiple states in the U.S., resulting in 358 cases, 133 hospitalizations, and one death.

- Listeria Outbreak Linked to Cantaloupes (2011): This outbreak is one of the deadliest in U.S. history. Contaminated cantaloupes from a farm in Colorado led to a Listeria monocytogenes outbreak, resulting in 147 illnesses, 143 hospitalizations, and 33 deaths across 28 states.

- Hepatitis A Outbreak Linked to Frozen Strawberries (2016): A multi-state outbreak of Hepatitis A was linked to frozen strawberries imported from Egypt, used in smoothies by a popular chain. This outbreak resulted in 143 cases across nine states, with 56 hospitalizations.

These examples highlight the severe health risks posed by biological hazards in food and the critical need for preventive measures and quick responses to contain these outbreaks.

Implementing Food Safety Practices in Food Manufacturing and Processing

Understanding biological food hazards is the first step. The subsequent and most crucial step is implementing measures to prevent these hazards, especially for food manufacturing and processing companies.

Role of Food Safety Management Systems

A structured Food Safety Management System (FSMS) is a strategic asset for food manufacturers and processors.

An FSMS provides a systematic method to identify, monitor, and control food safety hazards within a production cycle. It encompasses everything from raw material procurement to final product distribution.

The primary goal is to ensure the food products are safe for consumption and meet regulatory requirements. With an effective FSMS, companies can not only manage biological hazards in food but also chemical and physical hazards.

Hazard Analysis and Critical Control Points (HACCP)

HACCP, an internationally recognized food safety system, is designed to control hazards threatening food safety. It operates on seven core principles, including conducting a hazard analysis, identifying critical control points (CCPs), and establishing corrective actions, among others.

Through HACCP, food manufacturing and processing firms can effectively prevent, reduce, or eliminate potential biological food hazards throughout the production process. The HACCP plan is typically customized to fit specific production lines, product types, and biological food hazards.

Detection and Testing Methods for Biological Hazards

Detection and testing of biological hazards are crucial for food safety assurance. Whether part of your environmental monitoring program (EMP) or through raw-material, in-process, or finished-product testing, various methods are used depending on the type of hazard.

- Microbial Culture Techniques: Traditional method where samples are cultured on selective media to isolate and identify specific pathogens like Salmonella or E. coli. These techniques can be time-consuming and require expertise.

- Rapid Testing Methods: These include methods such as immunoassays (ELISA) and Polymerase Chain Reaction (PCR) techniques, which are quicker and more sensitive. PCR, for instance, can identify the genetic material of pathogens, providing a high level of accuracy.

- Next Generation Sequencing (NGS): NGS allows for the identification and quantification of all microorganisms in a sample, not just those that can be cultured. This method is highly comprehensive but requires sophisticated equipment and expertise.

- Biosensors: These provide rapid, real-time detection of pathogens. While still under development, they show great promise for future food safety testing.

GFSI-Benchmarked Food Safety Platforms

The Global Food Safety Initiative (GFSI) provides benchmarked platforms that guide food safety management efforts across the globe. These platforms are based on rigorous standards that tackle food safety from multiple angles, including the prevention of biological hazards. They encourage firms to cultivate a food safety culture, integrate food safety into business strategies, and establish robust food safety management systems.

Adopting GFSI-benchmarked platforms like SQF, BRCGS, or FSSC 22000 can significantly help companies strengthen their defense against biological hazards and achieve GFSI certification against one of these standards.

Training and Education

Staff training and food safety education play a critical role in the effective prevention and control of biological hazards. Employees at all levels should understand potential hazards, the importance of following safety protocols, and the consequences of non-compliance.

Training programs should cover proper hygiene practices, cleaning and sanitization processes, temperature control, and more. Regular refresher courses can help keep staff updated on new threats, evolving regulations, and advanced preventive measures. Understanding how microbes grow using the FATTOM acronym can help, too.

Regular Audits and Inspections

Regular audits and inspections are fundamental to maintaining a high standard of food safety. They offer a reality check on the effective functioning of the food safety management system, adherence to HACCP principles, and compliance with other food safety protocols.

Audits can help identify potential risk areas, monitor critical control points, and provide insights for continuous improvement. Additionally, third-party food safety audits can offer an unbiased view of the company’s food safety status, boosting consumer trust.

Traceability and Recall Systems

In an interconnected global food supply chain, a robust traceability and recall system is more crucial than ever.

Traceability systems allow companies to track a product’s path from farm to fork. In case a biological hazard is detected in a product batch, these systems facilitate rapid recall, preventing further spread and consumption. Such a proactive approach not only safeguards public health but also protects the brand reputation by demonstrating the company’s commitment to food safety.

The Final Word: Embracing Safety and Taking Action

The journey of understanding biological food hazards doesn’t end with merely identifying them and their potential impact. The most crucial step is to act. For food manufacturing and processing companies, implementing measures to prevent these hazards from entering the food supply chain is an absolute necessity.

By adopting rigorous safety practices and standards such as HACCP, GFSI-benchmarked platforms, and robust Food Safety Management Systems, companies can significantly mitigate risks associated with biological hazards. Emphasizing staff training, conducting regular audits, maintaining strong traceability and recall systems, and rigorously following QA and QC protocols are crucial elements of this preventive approach.

Your commitment to food safety, your vigilance in hazard prevention, and your dedication to quality not only protect consumers but also contribute to a healthier, safer world.