BRCGS certification is a third-party audit and certification program for food manufacturers that verifies your food safety and quality management system meets the BRCGS Global Standard for Food Safety (currently Issue 9). Many retailers and brand owners require BRC certification (commonly used as a shorthand term) as a supplier-approval requirement.

This article answers several questions for food sites:

- What is BRCGS certification (or BRC certification)?

- What are the steps toward achieving BRCGS certification?

- How much does BRCGS certification cost (and how much does a BRCGS audit cost)?

- What should I expect during a BRCGS audit?

Let’s dive in.

What Does BRCGS Mean?

People often use the acronyms “BRCGS” and “BRC” interchangeably to refer to BRCGS food safety certification. What does BRC mean? And what does BRCGS mean?

- BRC originally referred to the British Retail Consortium, the UK retail trade association that developed the early food standard.

- BRCGS uses the brand message “Brand Reputation through Compliance” and is commonly expanded as Brand Reputation through Compliance Global Standards.

Today, BRCGS certification is one of the most widely recognized GFSI food safety schemes and is often required by major global retailers, quick-service restaurants, and brand owners.

What is BRCGS Certification (BRC Certification)?

BRCGS certification is a third-party, accredited certification program that verifies your facility’s food safety and quality management system meets the BRCGS Global Standard for Food Safety (Issue 9). As said earlier, “BRC certification” is common shorthand for the same certification.

You earn certification by completing a formal BRCGS certification audit performed by a registered Certification Body, such as FSNS Certification & Audit. The auditor evaluates whether your programs are implemented effectively, documented appropriately, and consistently followed in daily operations. If your site meets the requirements and achieves the required grade, you are awarded certification and can be listed in the BRCGS Directory (depending on program settings).

BRCGS is also a GFSI-recognized scheme, alongside FSSC 22000 and SQF, which share core food safety foundations (risk-based controls, HACCP principles, prerequisite programs, and verification). BRCGS often stands out for its explicit expectations around:

- Brand protection and senior management commitment.

- Traceability and mass balance readiness.

- Food safety culture and continuous improvement.

- Operational discipline, where written procedures match real practices.

For many manufacturers, BRCGS certification is not just an audit outcome – it is a structured way to demonstrate control of food safety and quality to customers, auditors, and global supply chains.

Access the BRCGS Directory

The BRCGS directory lists all audits conducted against a BRC standard.

It’s worth noting that the BRCGS Global Standard is the first standard to introduce food safety culture requirements and the first to be GFSI benchmarked. Today, it is accepted by 70% of the top 10 retailers worldwide, 60% of the top 10 quick-service restaurants, and is adopted by more than 22,000 sites in 130 countries.

The BRCGS platform contains rigorous and detailed requirements, but they are made easy for you to understand. On top of that, they’re also designed to be efficient and help you improve your processes so you can eliminate the need for multiple audits.

Achieving BRCGS certification requires passing a third-party audit from a registered Certification Body.

What is the Difference Between GFSI and BRCGS?

Now that we’ve mentioned the Global Food Safety Initiative (GFSI), let’s answer another common question: What is the difference between GFSI and BRCGS?

While GFSI is a benchmarking organization that sets standards for food safety certification schemes, it does not offer certifications itself. In contrast, BRCGS is one of the certification schemes recognized by GFSI.

As an analogy, think of GFSI like a coach who sets the rules but does not play the game. Meanwhile, BRCGS is like someone who plays the actual game.

How Do I Get BRCGS Certification?

Let’s look at how to apply for BRCGS certification. It’s a multi-step process that begins with some research:

Step 1: Review the BRCGS Standard

Visit the BRCGS website to download and review the BRCGS Version 9 PDF. It’s helpful to download the BRCGS Issue 9 Interpretation Guide PDF to aid in understanding the standard while you’re there.

Step 2: Define Scope and Take a Training Course

Identify the scope and requirements of the Standard as they pertain to your facility. Attending a BRCGS educational course, like those offered by FSNS, will help provide clarity and direction.

Step 3: Perform a Self-Assessment or Pre-Audit

Perform a self assessment against the requirements of the Standard to determine if your organization is ready for a formal BRCGS audit. BRGCS has a self-assessment tool on its website. In addition, FSNS Certification & Audit performs BRCGS pre-audits to help organizations prepare for their BRCGS audit.

We provide tips on how to prepare for a BRCGS Food Safety audit here.

Step 4: Schedule and Undergo the BRC Audit

Schedule a BRCGS audit with a registered Certification Body, such as FSNS C&A, which is a 2X BRC Certification Body of the Year award winner.

Step 5: Correct Non-Conformities and Achieve Certification

The Certification Body performs the BRCGS audit at your facility to verify if your operations are undertaken in accordance with the Standard. Afterward, you will receive a BRCGS audit report that shows any non-conformities.

If your facility successfully completes the audit, addresses any non-conformities (if needed), and achieves the required grade, you will be awarded BRCGS certification, and your company will be added to the BRCGS directory.

Check out this blog post to discover the 10 most common BRCGS audit non-conformities our auditors find. And in the article, we reveal the top five BRCGS audit findings for mature vs. new sites.

How Much Does BRCGS Certification Cost?

While BRCGS Food Safety certification costs can vary by facility size and readiness, here’s a general estimate of what to expect, starting with acquiring the Global Standard and supporting documents.

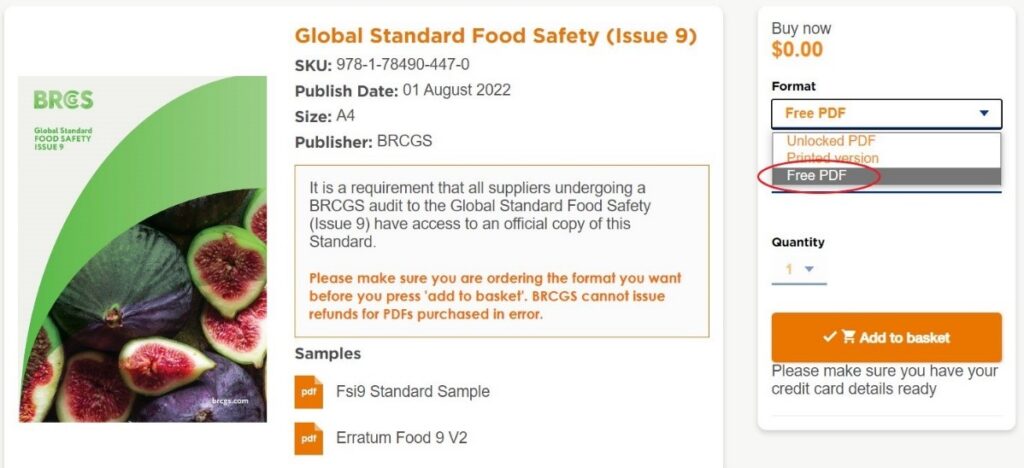

BRCGS asks you to purchase the current BRCGS Global Standard for Food Safety, which is Version 9 as of this writing. The standard costs $177.12 (U.S.) on the BRCGS website. However, if you select “Free PDF” from the dropdown menu, you can download a copy for free, as shown in the image.

Select “Free PDF” in your cart on the BRCGS website to download the current Global Standard for free.

The BRCGS Issue 9 Interpretation Guidelines, which are not necessary but are a helpful resource, currently cost $236.99 (U.S.).

In addition, you will need to pay a registered Certification Body to perform the audit, which varies depending on the Certification Body, but typically costs around $7,000 (U.S.), plus travel expenses for the auditor. It’s also a good idea to perform a pre-audit to ensure your facility and employees are ready, which can cost about $6,000.

All totaled, the cost of BRCGS certification can be around $13,000.

These costs not only reflect audit and training fees, but also represent an investment in continuous improvement, reduced product recalls, and access to new markets—benefits that far outweigh the initial expense.

Also, FSNS Certification & Audit offers a 15% discount for new customers, so contact us for a quote for your BRCGS certification audit.

What Certification Bodies Audit to the BRCGS Global Standard?

The process of earning a food safety certificate and getting the benefits of BRCGS certification is a straightforward one. However, you need to find a BRCGS registered Certification Body to successfully perform a BRCGS audit and earn your certification.

FSNS Certification & Audit (FSNS C&A) is a legal entity accredited under ISO 17065 to conduct certification audits according to the BRCGS Global Standard for Food Safety. We provide third-party certification and audit services with consistency, impartiality, and integrity. In addition, FSNS C&A is a 2X BRC Certification Body of the Year award winner.

For inquiries about BRCGS audits, contact one of our specialists.

It takes company-wide commitment to achieve BRCGS certification, but many of the top retailers require it before you can do business with them.

What are the Benefits of BRCGS Certification?

If you’ve been interested in earning a GFSI food safety certification such as BRCGS but have not taken concrete steps toward it, here are five benefits of BRCGS certification to consider:

Protect Your Customers With a GFSI Food Safety Certification

- Complying with BRCGS’s food safety and quality standards is crucial for protecting customers from health risks.

- The BRCGS framework aids in implementing best practices in food preparation, personal hygiene, and facility cleanliness.

- Adherence to the standards teaches methods to safeguard consumers from food poisoning, allergic reactions, and risks from contaminated food.

Enhance Brand Image and Market Credibility

- BRCGS Global Standard certification is an internationally recognized mark of food quality and safety, enhancing trust and reputation.

Achieve a Strong ROI With BRCGS Certification (BRC Certification)

Earning BRCGS certification will not be easy; you may need to invest time and resources into food safety training and other Food Safety Certificate requirements. However, diligently going through the certification process enables you to do the following:

- Implement the best methods of product safety management on your site.

- Avoid expensive fines caused by food safety failures.

- Reduce food waste, meal comps, and their accompanying costs.

- Avert scandals brought about by customer complaints or negative reviews.

Expand into Top Retailers

- Holding a GFSI food safety certification such as BRCGS opens markets limited to certified manufacturers.

- Major retailers and quick-service restaurants require suppliers to maintain GFSI certification.

Grow Your Business

Throughout the BRCGS certification process, you will need to be hands-on with how your facility has been complying with the BRCGS’s food safety guidelines. Once you’ve passed the assessment and earned your BRCGS certification, you can reap the following benefits:

- Assurance of a robust food safety system.

- Confidence in having competent staff.

- Focus on core tasks and long-term business growth strategies.

A BRCGS audit involves many steps that encompass your entire production process, but preparing ahead of time will help you know what to expect and be ready for a successful audit.

What to Expect During a BRCGS Audit

The current BRCGS Global Standard (issue 9) includes the following requirements for a BRCGS audit:

- Senior management commitment: Company leaders should promote the implementation and continuous improvement of your food safety program.

- HACCP (food safety plan): You need a HACCP plan to help guide your food safety program.

- Food safety and quality management systems: This includes thorough documentation of your processes to ensure personnel are trained to safely manage food production.

- Site standards: Food production sites must meet appropriate safety standards.

- Product controls: Your organization must establish controls for areas such as allergen management and product testing.

- Process controls: This ensures your organization follows your HACCP plan.

- Personnel: Your personnel must be properly trained, use proper hygiene, and wear PPE.

- High Risk, High Care, and Ambient High Care Production Risk Zones: You must enact controls over products at risk for pathogen contamination to maximize safety.

- Traded Products: Facilities that buy and sell food products must follow processes to avoid contamination.

Preparing for a BRCGS audit requires cross-functional team involvement and a thorough understanding of the Standard. A pre-assessment audit can help identify gaps and ensure your documentation, site practices, and personnel are ready.

Download Our BRCGS Audit Checklist to Prepare

The BRCGS audit itself will typically take 2-3 days to complete. While it can be stressful, preparing your team beforehand with a pre-assessment audit will help ensure your organization is ready to meet the requirements for a successful audit. Our free BRCGS Audit Checklist helps you prepare.

Here is an outline of how a BRCGS audit will usually take place:

BRCGS Audit Opening Meeting

The auditor and your team will discuss the scope of the audit and agree on an agenda. It’s also the ideal opportunity for the auditor to meet anyone on your team who will be involved with the audit.

- Confirm scope of audit

- Outline the agenda

- Gain understanding of the roles of your team members

- Explain audit methodology

Conduct Site Audit

The auditor will evaluate your production processes to identify whether they comply with current Good Manufacturing Practices (cGMPs). They will focus on all areas of your organization that are pertinent to the BRCGS Global Standard, such as manufacturing, storage, production equipment, and site safety.

The auditor will walk through your facility to evaluate any discrepancies between your documented processes and daily operations. They may interview personnel to ensure compliance. It’s a good idea to have a senior staff member available to explain their areas of expertise to the auditor to aid in understanding.

A BRCGS site audit will typically include a product changeover so the auditor can evaluate if personnel follow documented procedures to adequately clean equipment, change PPE, and follow any other required processes.

Review Documented Processes

The auditor may review your standard operating procedures (SOPs), processes, and other policy documents during a desk audit or during the site audit. They will compare written records with the relevant sections of the Standard against which you are being audited.

They want to ensure that what is documented is followed during daily operations. For example, there should be no discrepancy between a HACCP flow chart and the activity of production personnel. The auditor is looking for consistency and conformity with all documented processes.

Interview Senior Personnel

At some point during a BRCGS audit, the auditor will talk to key personnel to identify their role and, possibly, observe them performing a routine activity to ensure it conforms with documented procedures. This provides the auditor insight into whether staff have been properly trained.

This step is also an opportunity for senior staff to demonstrate a commitment to food safety throughout the organization.

Equipment Evaluation

The auditor will inspect some production equipment and observe cleaning practices to determine if they are consistent with documented procedures. They may request that the equipment be disassembled so they can observe more closely and possibly ask for swab results.

Traceability Audit

This can be the most challenging aspect of a BRCGS audit since it requires that your team demonstrate complete control over your production process, from accepting raw materials to shipping finished products.

The auditor will select a product made on a particular day. Your team will then need to demonstrate complete traceability, which includes the following:

- Trace each raw material to its supplier.

- Show the number of units manufactured in the batch.

- Show each point along the supply chain.

- Identify where each product was shipped.

Demonstrating traceability takes complete commitment from your team and requires that you have an effective management system in place.

Mass Balance Audit

Part of the traceability audit includes the auditor checking the quantity of incoming raw materials to the quantity used in your finished products, known as a “mass balance”. The auditor will choose an ingredient and ask you to show where it has been used in production. You must be able to account for where all ingredients of the chosen batch number have been used.

If all ingredients haven’t been used, you must provide explanation that proves you understand the nature of the variance. For example, if your facility uses sugar in a finished product, you must be able to say the balance hasn’t yet been used and is stored in a particular area of the facility.

The BRCGS Global Standard allows from some variance in mass balance due to waste, portion variances, and other factors, but be prepared to account for all your raw materials.

BRCGS Audit Label Review

Typically, during the traceability portion of the audit, the auditor will select a finished product and perform a label review. They will ensure the nutritional information, ingredients, allergen declaration, or other pertinent information is consistent with your documented product specifications.

Closing Meeting

Finally, the auditor will hold a closing meeting with the same team that participated in the opening meeting. They will discuss the audit results, including any non-conformities. The auditor will also provide final results/grades. In the event of a non-conformity, your team must submit corrective actions for each one prior to submission of the overall report to BRCGS to receive certification.

If your organization passes the BRCGS audit, you will receive a certificate to verify your achievement.

Why Choose FSNS Certification & Audit?

If you’re looking for a third-party food safety audit company, FSNS C&A has you covered.

- Our auditors have an average of 14 years of experience in food manufacturing, helping them provide exceptional service.

- 99% of our clients are satisfied with our responsiveness to calls and email.

- 99% of our clients are satisfied or extremely satisfied with our auditors.

- 2X BRC Certification Body of the Year Award Winner.

If you have questions, are ready to schedule a BRCGS audit, or anything in between, contact our Certification & Audit specialists for help.

What is BRCGS certification?

BRCGS certification is a third-party certification that verifies a site meets the requirements of the BRCGS Global Standard for Food Safety through an accredited audit.

How long does it take to get BRCGS certification?

Timelines depend on readiness. Many sites need weeks to months to close gaps, train personnel, and finalize documentation before scheduling the certification audit. The BRCGS audit itself will take 2-3 days.

How much does a BRCGS audit cost?

Audit cost depends on the Certification Body, but typically runs around $7,000 (U.S.), plus travel expenses for the auditor. It’s also a good idea to perform a pre-audit to ensure your facility and employees are ready, which can cost about $6,000. So, budget >$13,000 for your BRCGS audit. FSNS Certification & Audit offers 15% off a BRCGS audit for first-time customers.

What is the purpose of BRCGS?

BRCGS provides a structured standard for managing food safety and quality so manufacturers can demonstrate control of hazards, traceability, and compliance to customers.

What’s the difference between BRC and BRCGS?

BRC historically refers to the British Retail Consortium, while BRCGS refers to the global standards and certification program developed from that origin.

What does BRCGS stand for?

BRCGS is commonly expanded as Brand Reputation through Compliance Global Standards.