SQF audits are one of the most frequent that our Certification & Audit team performs at food facilities of all sizes and in all markets. It’s an ideal GFSI-benchmarked certification for sites that are new to food safety certification and those with years of certification experience. Let’s dive into SQF audit basics for those who are new to SQF certification.

SQF Meaning Explained

Let’s start with a basic question: What does SQF stand for?

SQF is an acronym for “Safe Quality Food”.

Overseen by the Safe Quality Food Institute, SQF is a global food safety program whose goal is to ensure food safety.

It is based on Hazard Analysis Critical Control Points (HACCP) and is recognized by the Global Food Safety Initiative (GFSI). Many retailers and manufacturers worldwide require SQF certification or similar before purchasing food products from other companies. Doing so provides reassurance that your facility has been evaluated by a third party food safety audit company, showing your commitment to food safety.

What is SQF Certification?

That raises the next question: What is SQF certification?

SQF certification is an independent, third-party validation that your product, process, or service complies with the standards outlined in the SQF code (currently SQF edition 9; however, SQF edition 10 should be released in 2026). This is done through an SQF audit, which is the formal evaluation process used to verify that your facility meets SQF standards.

What are the Benefits of SQF Certification?

Passing an audit and achieving SQF certification provides your company with several benefits, including…

- Establishment of a robust food safety management system.

- Assurance for retailers and other distributors that your products have been produced and prepared according to globally recognized standards.

- Access to top retailers, helping you expand your sales.

- Decreased risk.

- Stronger brand image.

Successfully passing an SQF Audit builds trust with customers and demonstrates your facility’s commitment to excellence in food safety and quality.

What are the Different SQF Programs?

To get started on your way to SQF certification, you first need to select the appropriate food safety program.

The Safe Quality Food Institute offers 5 different SQF programs from which to choose for your facility. This offers the flexibility to use the program that best fits your company’s size and needs.

Here’s a glance at them:

| Program | Who’s It For? | Prerequisites | GFSI-Benchmarked? |

| Food Safety Program | All food producers | None | Yes |

| Fundamentals Program | Small & medium companies | None | Yes |

| Quality Program | Sites with robust food safety plans | SQF food safety plan or similar | Yes |

| Foodservice Program | Foodservice businesses | None | No |

| Food Retail Program | Food retailers | None | No |

How Much Does SQF Certification Cost?

SQF certification cost will depend on the steps your facility must take to ensure your product, processes, or service comply with the standards defined in the SQF code. Some facilities have food safety programs in place and may be ready to pass an SQF audit today. Other facilities may require quite a bit of work before being able to pass an audit.

No matter where your facility falls on the spectrum, you need to schedule and pass an SQF audit from a licensed certification body, such as FSNS Certification & Audit.

A 2-day SQF certification audit from FSNS C&A typically costs under $6,000.

Again, audit cost can vary depending on length and complexity. View it as an investment in your facility’s food safety program and quality goals. Certification is also required to access many retailers, which helps you recoup the cost of the SQF audit and boost revenue.

Bear in mind that FSNS Certification & Audit offers 15% off an SQF audit for new customers. Reach out here if you’re interested.

How Long Does an SQF Audit Take?

An SQF certification audit typically takes no more than two days to complete. Understand that this includes only the on-site portion of the audit process during which the auditor will visit the site to talk to staff, review documents, evaluate your production area, and perform other audit duties.

This does not include pre-audit administrative work, such as onboarding, scheduling, preparing the final report, and delivering the report.

Who Performs an SQF Audit?

Only SQFI-licensed Certification Bodies (CBs) are approved to conduct SQF audits and issue certificates. These CBs are accredited to the international standard ISO/IEC 17065. All SQF CBs are held to standards and annual assessments to meet requirements for SQFI.

FSNS Certification & Audit is an SQFI-licensed certification body.

What Happens During an SQF Audit?

An SQF Audit typically includes a document review, facility inspection, employee interviews, and verification of food safety and quality systems. The SQF audit is conducted by a Certification Body, such as FSNS Certification & Audit, and follows a detailed checklist based on the SQF Code.

How Do I Get SQF Certified?

Since an SQF certification involves the public’s health and safety, the process of earning it is deliberately designed to be robust and meticulous. It includes the education, implementation, auditing, and maintaining of safety standards within your facilities.

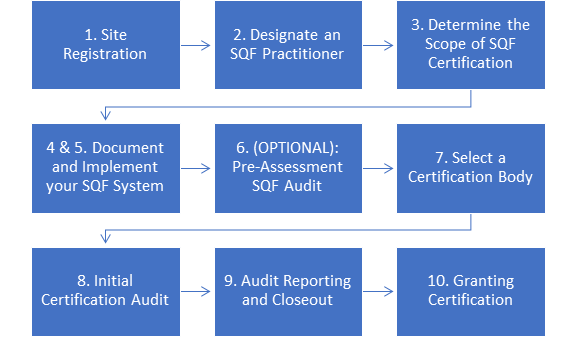

Here is a simple outline of the steps you will need to take to earn SQF certification.

- Site Registration

- To be considered for SQF certification, register your facility on the SQFI assessment database. Note that there is a fee for registration and annual renewals. You need to register your site with SQFI prior to the start of the initial certification audit.

- Designate an SQF Practitioner

- Appoint a full-time employee to act as your SQF practitioner. This person will need to complete a HACCP-based training course and, ultimately, gain a working knowledge of SQF code, and meet the requirements outlined below.

- You need to designate a primary and substitute practitioner who meet the following requirements:

- Must be employed by your site.

- Hold a position of responsibility to managing an SQF program.

- Have completed a HACCP/PCQI training course.

- Be competent to implement and maintain HACCP-based plans.

- Understand the SQF code (FSNS offers an SQF practitioner training course).

- You may have more than one SQF practitioner within your team so you can efficiently oversee the development and implementation of the SQF food safety program in your facility. Having a “substitute” at minimum is required.

- Determine the Scope of SQF Certification

- Next, you must determine the scope of certification for your SQF audit, meaning the food sector categories, products, and processes that will be included in your system.

- The scope determines what elements of the SQF code are applicable to your SQF certification. There are several Food Sector Categories to review to determine where your products fit, such as for egg processing; dairy food processing; slaughtering, boning, and butchering; and more.

- Once you identify your Food Sector Categories, you will be responsible for implementing the system elements and your relevant GMP module based upon your scope.

- Document & Implement Your SQF System

- This step requires the most time and resources. It requires documenting and implementing the requirements of the SQF code and developing your own SQF system.

- Programs, policies, procedures, work instructions, and specifications need to be developed and implemented to meet the requirements of the SQF code.

- Here a just a few examples of what must be implemented in your SQF food safety program:

- Records of all investigations, root cause analyses, and resolution of non-conformities, their corrections, and the implementation.

- Annual review and validation of critical food safety limits.

- Cleaning and sanitation activities and records.

- Proper handling and storage of food.

- Internal audits and inspections.

- Our auditors documented the top 10 reasons they find for SQF audit non-conformities here. Review the list to understand the common areas where facilities come up short.

- Pre-Assessment SQF Audit (Optional)

- A pre-assessment SQF audit is not required but is an excellent way to determine if your facility is on the right track before completing the certification audit. There may be onsite and remote review of your SQF system to help identify gaps in your implementation.

- Contact FSNS Certification & Audit to schedule a pre-assessment SQF audit.

- Get tips for preparing for your SQF certification audit here.

- Select a Certification Body

- Once selected, you and the CB will begin the set up to schedule your SQF audit, including confirming scope and required SQF code sections with your FSC.

- FSNS Certification & Audit is a licensed Certification Body.

- Initial Certification Audit

- A qualified and registered food safety auditor (or team) will check that your documentation meets the SQF code and that your activities are conducted according to your documented policies, procedures, and specifications.

- Audit Reporting and Closeout

- The auditor(s) gather evidence of compliance or non-compliance with the appropriate SQF code by reviewing documentation, interviewing staff, observing operations, and other tactics. You are given a score in your audit report based on the findings.

- Grant Certification

- The Certification Body will determine based on evidence gathered during its SQF audit whether you receive certification or not. If your site meets requirements, you will receive a copy of your site’s certification within 10 days.

How Long Does SQF Certification Last?

Your site’s SQF certification is valid for 12 months. To maintain it, you must complete a re-certification audit every year within 30 days before or after the anniversary of your initial certification.

If your site receives a “C – Complies” rating during a certification audit (rather than “E – Excellent” or “G – Good”), a surveillance audit is required six months after certification to verify corrective actions.

At least once every three certification cycles, your regular annual audit will be conducted as an unannounced audit instead of a scheduled one. This unannounced audit fulfills the yearly recertification requirement for that year — it is not an additional audit.

What are the Most Common SQF Audit Non-Conformities?

Our auditors have performed hundreds of SQF audits, and here are the most common non-conformities that they find:

- Failure to have senior site management review the SQF system each year.

- Failure to identify and document corrective and preventative actions.

- Failure to validate each element defined in GMPs.

- Failure to follow manufacturer procedures for cleaning and sanitation.

- Improper food handling and processing.

View the full list of SQF audit non-conformities here.

Use an SQF Audit Checklist to Prepare

Download our SQF Audit Checklists to help prepare for your audit. We have two checklists available, depending on your Food Sector Category:

SQF Audit Checklist for Food Sector Categories 10-22, 25, & 33

SQF Audit Checklist for Food Sector Categories 7-9

How Long Does it Take to Get SQF Certified?

The SQF audit duration is no less than two days, including document reviews and facility assessments. However, the whole process of having your site evaluated for SQF certification can take anywhere from 6 months to a year or more.

Here are some of the factors that can speed up or slow down your SQF certification process:

- Existing certifications.

- Correct implementation and documentation from proper training.

- The scope of the audit.

- The number and complexity of processes to be assessed.

- The ease of communication with on-site personnel.

Questions about an SQF Audit or Certification?

We understand that an SQF audit and certification is crucial to your success, and we’re here to help make the process more efficient for you.

FSNS Certification & Audit (FSNS C&A) is an independent and accredited food safety audit company. Through our objective assessment process, we ensure that your site meets global standards and stays ahead of the competition.

Contact FSNS C&A if you need help securing an SQF certification for your facility.

SQF Certification FAQs

What is SQF Certification?

SQF certification is a globally recognized food safety certification that proves your facility follows rigorous food safety and quality standards. It’s issued by a licensed Certification Body after a formal SQF audit.

This certification can open the door to new markets, improve brand trust, and reduce food safety risks.

How Much Does SQF Certification Cost?

A typical 2-day SQF certification audit from FSNS Certification & Audit costs under $6,000. However, your site may need to invest in upgrading your food safety management system to be able to pass an audit. Those costs vary depending on the state of your current system.

Who Can Perform an SQF Audit?

Only an SQFI-licensed Certification Body, such as FSNS Certification & Audit, can perform an SQF audit.

What is the Difference Between SQF and HACCP?

HACCP is a preventive food safety system that identifies and controls biological, chemical, and physical hazards in production, while SQF is a certification program that incorporates HACCP principles into a broader, GFSI-benchmarked quality management system. In short, HACCP is a method, and SQF is a formal certification that verifies a facility follows HACCP-based and other quality standards.

What Does SQF Stand For?

SQF is an acronym for “Safe Quality Food”. Overseen by the Safe Quality Food Institute, SQF is a global food safety program whose goal is to ensure food safety.

How Do I Pass an SQF Audit?

It depends on the current state of your food safety management system. For sites with robust, mature systems, passing an audit may require few changes to your current system. For sites new to food safety certification, several additional processes may need to be added to your management system before you can pass. Our blog provides details on how to get SQF certified.