Reviewed and Approved by Steven Rogers, Chemistry Manager, Certified Laboratories

1-Minute Summary

- Maximum Residue Limits (MRLs) define allowable pesticide concentrations in food, aligned with national and international safety standards.

- In the U.S., FDA and USDA enforce pesticide regulations in coordination with the EPA; non-compliance risks legal action and market exclusion.

- The USDA provides a Pesticide MRL Database to check specific pesticide limits by commodity, available online with both free and premium options.

- Pesticide residue testing labs use a combination of advanced techniques for comprehensive pesticide residue analysis, including GC-FPD, LC-MS/MS, and GC-MS/MS.

- When choosing a testing lab, it’s vital to consider ISO 17025 accreditation, expertise, technology, and customer service.

Pesticide residue testing is an essential aspect of maintaining food safety and quality. An increasing number of consumers want “clean” products that are free of pesticides.

This means food safety professionals need to understand Maximum Residue Limits (MRLs), how to choose a testing laboratory, analytical methods used for pesticide residue analysis, and more.

This guide is designed to equip you with the knowledge you need to understand pesticide testing and ensure compliance with regulations while satisfying consumer demands.

Understanding MRLs: Definition, Importance, and Compliance

Pesticides are a vital tool used in agriculture to improve yields, protect crops, and contribute to a safe, abundant food supply. But many consumers today are wary of pesticide residue on their food.

With that in mind, we need to define a key concept when it comes to pesticide residue and food safety: Maximum Residue Limits (MRLs).

MRLs signify the highest allowable concentration of pesticide residues in food products.

Established by regulatory agencies, these limits act as a safety threshold to ensure consumer health protection. MRLs are vital in maintaining the trust of consumers and are closely aligned with both national and international safety standards.

Importance of adhering to MRLs

In the U.S., the FDA and USDA have pesticide regulations and their own monitoring arms, but they both work in tandem with the Environmental Protection Agency (EPA), which is the true regulatory body with respect to pesticide use. Failure to comply can result in legal action and loss of market access.

Ensuring that pesticides used in food production do not exceed levels that are known to be safe also helps in protecting public health and preserving the integrity of the food supply chain.

The FDA’s role includes setting tolerance levels, while the USDA Pesticide Data Program helps in monitoring compliance. These regulations are designed to harmonize with international norms and provide a consistent framework for food safety across countries.

Using the Pesticide MRL Database

The USDA provides access to a helpful database that allows you to search for the Maximum Residue Limits of specific pesticides by commodity, such as almonds, lettuce, or different types of berries.

Access the USDA MRLs database list here.

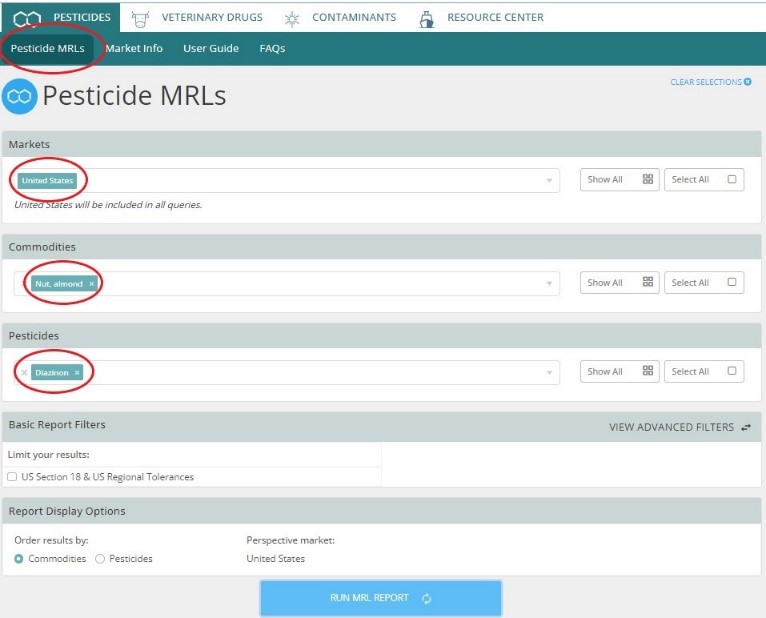

You will need to establish a free account to use the database. Premium subscriptions are also available for a fee. The image below shows how to use the MRLs database.

- Once logged it, choose “Pesticide MRLs” at the top of the screen.

- Select the market (the U.S. in this case).

- Choose the commodity. Here, we chose “Nut, almond”.

- Choose which pesticide you want to search (“Diazinon” in this example).

- Select “Run MRL Report” to discover the MRL in ppm.

International Regulations on Pesticide Residue Testing

Navigating international regulations on pesticide residue testing is a complex task, as standards can vary widely across different regions.

The Codex Alimentarius, European Union, U.S. EPA, and other international regulatory bodies have varying Maximum Residue Limits for pesticides. European standards are often more numerous and stringent, covering a wider range of substances and setting lower allowable MRLs.

It’s also noteworthy that when a specific pesticide lacks an established MRL, a default limit of 10 parts per billion (ppb) is commonly applied. Understanding these differences is crucial for professionals in industries that must comply with international regulations.

In these cases, choosing a pesticide testing laboratory that can work within any regulation can help you cut through the confusion.

Pesticide Residue Analysis Methods: An In-Depth Look

Laboratories predominantly use a combination of advanced techniques for comprehensive pesticide residue analysis. These techniques often include the following:

- Gas Chromatography with Flame Photometric Detection (GC-FPD)

- Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS)

- Gas Chromatography-Tandem Mass Spectrometry (GC-MS/MS)

Gas Chromatography with Flame Photometric Detection (GC-FPD)

GC-FPD is particularly useful for the analysis of specific pesticides that contain phosphorus or sulfur bonds, such as Chlorpyrifos. This method is generally used for a targeted approach to isolate unique pesticides and is not commonly used for full-scan testing.

Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) and Gas Chromatography-Tandem Mass Spectrometry (GC-MS/MS)

For broader analyses covering a more extensive range of pesticides, LC-MS/MS and GC-MS/MS are typically used. These methods leverage the power of mass spectrometry to separate and quantify multiple pesticides that might co-elute or interfere with each other in traditional HPLC or GC methods.

The dual mass spectrometry (MS/MS) systems allow for greater specificity and sensitivity, making them suitable for capturing a larger number of pesticides. While HPLC or GC methods can often measure only dozens of pesticides, MS/MS-based methods have the capability to measure hundreds.

The use of both LC and GC MS/MS systems is often necessary to capture a comprehensive range of pesticides that can’t be adequately measured by either system alone.

By focusing on these advanced methods, laboratories can offer more precise and extensive pesticide residue analysis, better adhering to regulatory requirements and ensuring the highest level of consumer safety.

Challenges in Pesticide Residue Analysis

Despite the advanced technology and methods used in the laboratory, pesticide residue analysis can still be complex due to several challenges, including:

- Complexity of Food Matrices: Different food items may contain numerous interacting compounds, making isolation of specific residues difficult.

- Detection of Low-Level Residues: Detecting residues at very low levels requires increasingly sophisticated equipment and expertise. With so much attention on pesticide residue today, MRLs could grow stricter over time, requiring even lower tolerances.

- Confusing Regulations: Understanding domestic and international regulations requires vigilance and flexibility in adapting testing protocols. The pesticides of interest and MRLs can differ depending on where you do business.

Pesticide residue analysis is a multifaceted field that requires deep understanding, technological prowess, and adherence to regulatory standards. That’s why it’s critical that you choose a laboratory testing partner capable of providing the pesticide residue analysis services you need.

That said, let’s look at how that’s done.

Pesticide Residue Testing Labs: A Look Inside

Consider these factors when selecting a lab for food pesticide residue testing to ensure that it meets your needs:

- ISO 17025 Accreditation: Pesticide residue testing labs must hold ISO 17025 accreditation, demonstrating competence and adherence to standardized procedures. This ensures the lab follows globally accepted testing methodologies, ensuring accuracy and reliability.

- Expertise: Assess the lab’s experience and technical proficiency in conducting pesticide residue analysis.

- Technology: Evaluate the lab’s equipment and methodologies, such as the use of advanced techniques like GC-FPD, LC-MS/MS, and GC-MS/MS.

- Customer Service: Consider the lab’s responsiveness, reporting capabilities, and overall approach to customer support.

Choosing the right pesticide residue analysis laboratory is a complex decision that demands thorough evaluation and understanding of the lab’s capabilities, accreditations, and alignment with regulatory requirements.

Certified Laboratories and Food Safety Net Services offer ISO 17025 accredited labs that can provide the services you need.