Aaron Pleitner

Aaron Pleitner

Aaron Pleitner

Aaron Pleitner

1-Minute Summary

- Food shelf life testing cost is incurred by baseline study setup and variable study design choices.

- Larger studies can reduce cost per data point, but only up to a point.

- Too many time points and replicates often deliver limited additional insight.

- Sequential testing of critical variables improves both clarity and cost control.

- Thoughtful planning protects both data quality and budget.

How to Balance Cost and Quality in a Shelf Life Study for Food Products

Shelf life testing plays a central role in confirming that food and beverage products remain safe, stable, and acceptable throughout their assigned storage period. The data generated supports regulatory compliance, labeling decisions, and quality assurance programs.

At the same time, shelf life studies require significant time, materials, and laboratory resources. Without purposeful planning, costs can escalate quickly, often without providing proportionate improvements in decision-making value.

This article outlines practical ways to design shelf life studies that deliver reliable results while keeping costs under control.

What is the Cost Structure of a Food Shelf Life Study?

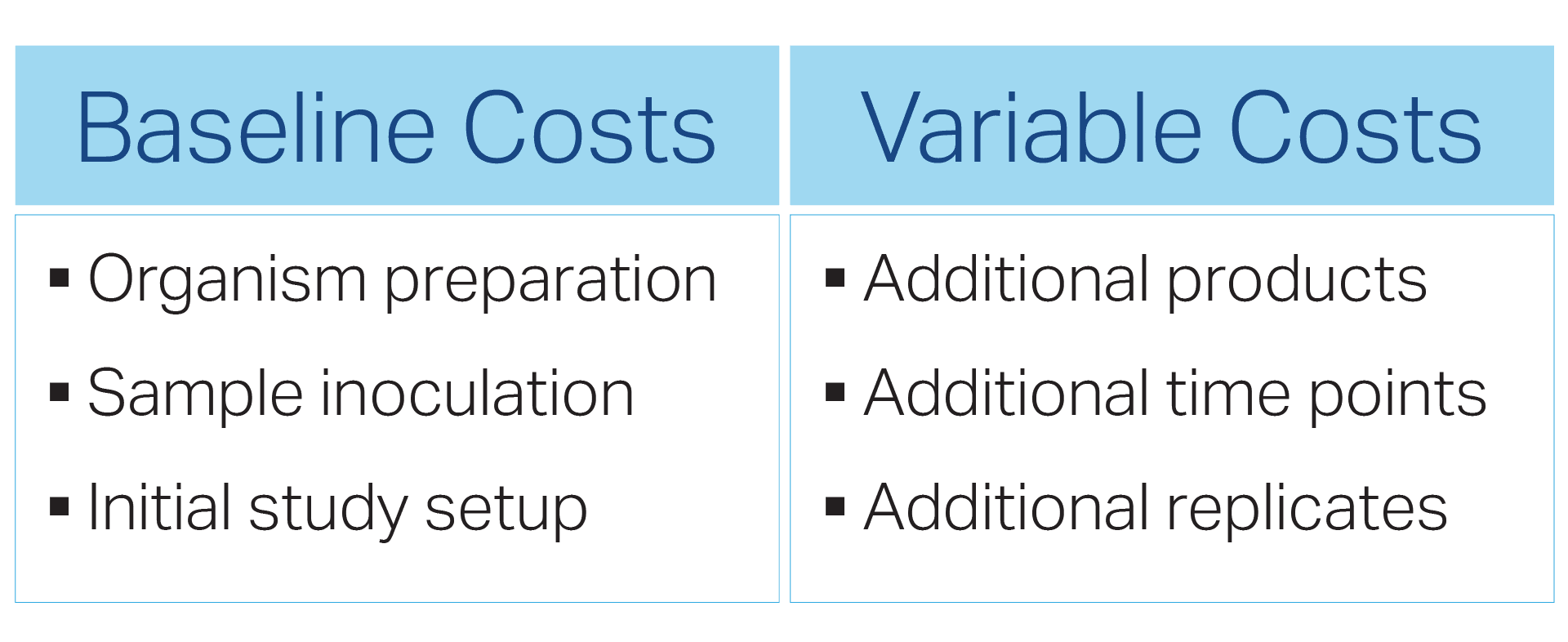

Food shelf life testing cost is determined by baseline setup expenses and variable testing components.

Baseline setup expenses occur at the start of the study and remain largely fixed, regardless of study size. These costs include:

- Organism preparation

- Sample inoculation

- Initial study setup

Baseline work ensures that all samples begin under consistent and controlled conditions, which is essential for valid comparison. Whether a study includes five samples or 50, most baseline costs remain the same. For this reason, efficient use of baseline resources is critical for cost control.

Variable costs increase as the study becomes more complex. These costs scale with:

- Additional products (formulations & package types)

- Additional time points

- Additional replicates

Each added variable increases sample preparation, incubation, enumeration, and reporting effort. When variables are not carefully controlled, total study cost can rise quickly without providing proportional analytical value.

Understanding how baseline and variable costs interact allows manufacturers to design shelf life studies that manage budgets while preserving scientific reliability.

Shelf life studies benefit from economies of scale, but those benefits are not unlimited.

Economies of Scale

As a study expands, many setup costs are distributed across more data points. This often lowers the cost per result. In practical terms, adding a few more time points or replicates usually costs less than expected because much of the infrastructure is already in place.

This effect allows manufacturers to gather more complete stability profiles without proportionally increasing total food shelf life testing cost.

Diminishing Returns

Eventually, however, additional testing produces smaller gains in useful information.

Beyond a certain point:

- Extra time points reveal little new trend information.

- Additional replicates improve statistics only marginally.

- Costs continue to rise while insight plateaus.

The most cost-effective studies stop just short of this threshold.

What are the Cost Differences Between Food Shelf Life Study Designs?

Food shelf life testing cost increases as time points, variables, and replicates are added, but not always in a linear manner.

Because baseline setup costs are shared, studies with more time points often cost less per data point than expected. However, beyond a certain level of complexity, added testing delivers diminishing analytical value relative to cost. Selecting the appropriate designtherefore requires balancing resolution needs with practical decision impact.

5-Time-Point Study Cost Breakdown

A typical 5-time-point design might include testing at 0, 4, 8, 12, and 16 weeks (based on target product shelf life of 12 weeks + 25% of target).

This structure:

- Captures major stability trends.

- Provides meaningful decision support.

- Keeps sample volume and cost manageable.

For many products, this approach offers an excellent balance between resolution and efficiency.

5-Time-Point Back Weighted Study Cost Breakdown

This is a 5-time-point study that leverages preexisting data to assign timepoints such as 2, 8, 10, 12, and 14 weeks.

While this maintains the number of measurements as the first 5-Time-Point design, the study foregoes early time points in lieu of more timepoints at the end of the study. The result is higher resolution data at the end of the study where failure is more likely. However, this necessitates preexisting data that the variables will at least withstand storage pressures in the first 50% of the target shelf life.

10-Time-Point Study Cost Breakdown

A 10-time-point study adds intermediate intervals such as 2, 6, 10, and 14 weeks.

While this doubles the number of measurements, the total study cost usually increases by only about 50–60 percent because baseline costs are shared. The result is higher resolution data that can be valuable for high-risk or high-value products.

Efficient Use of Variables in Study Design

Variables are where many shelf life studies become unnecessarily expensive.

Testing multiple formulations, packaging types, and storage conditions at once quickly multiplies sample counts and complicates interpretation.

A more efficient approach is to test variables sequentially.

For example:

- Identify optimal storage conditions first (e.g. temperature).

- Evaluate packaging under those conditions next (e.g. MAP, ambient, vacuum).

- Compare formulations only after both are defined (e.g. preservatives, intrinsic factors).

This progression reduces complexity, improves clarity, and prevents redundant testing.

Importance of Replicates and Trials

Replicates strengthen confidence in shelf life data, but they also increase workload and cost.

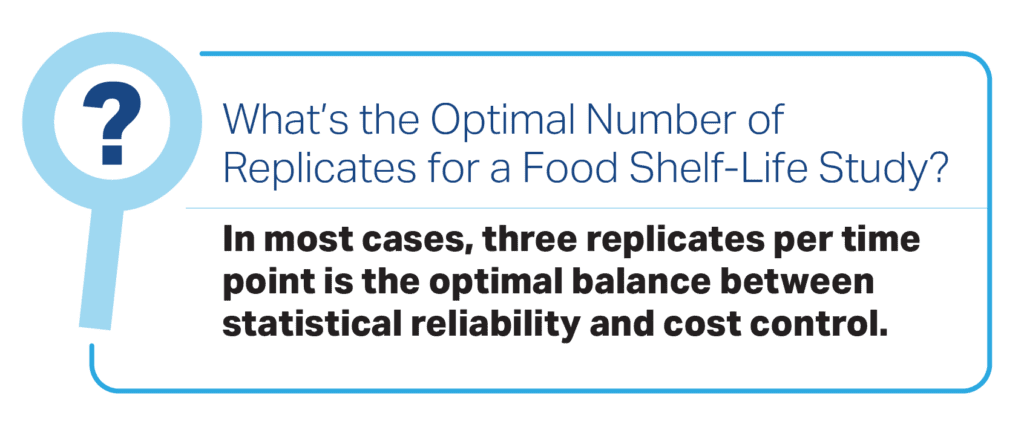

What Is the Optimal Number of Replicates for a Food Shelf Life Study?

For most food shelf life studies, three replicates per time point provide an acceptable balance between statistical reliability and cost control.

This level of replication allows manufacturers to identify meaningful trends while limiting unnecessary analytical workload. In some cases, two independent manufacturing or pilot trials with two to three replicates each may offer a practical alternative when budget or sample availability is limited. Additional replicates and number of individual production lots should take into account regulatory risk, safety impact, or commercial exposure.

Optimal Food Shelf Life Testing Cost Balances Quality with Dollars

Food shelf life testing cost does not have to be a barrier to a good study. With proper planning, studies can remain both efficient and scientifically sound.

Manufacturers control cost most effectively when they:

- Use baseline resources efficiently.

- Select time points intentionally.

- Isolate variables logically.

- Match replicate counts to real decision risk.

- Apply accelerated shelf life testing only when appropriate for chemical stability failure modes only, not biological.

A well-designed shelf life study delivers dependable, defensible data while respecting budget constraints.

If you are planning a shelf life study, the FSNS Contract Research Team (Lab+) can help translate your product goals into a study design that protects safety, supports compliance, and avoids unnecessary expense.