Reviewed and Approved by Ryan Welsh, M.S., Corporate Operations Support, Certified Group

1-Minute Summary

- The FATTOM acronym (also referred to as FAT TOM) helps food safety & quality assurance personnel know how to control microbial growth in food.

- FATTOM stands for Food, Acidity, Temperature, Time, Oxygen, and Moisture – the six factors that affect microbial growth in food.

- Managing these factors helps reduce risks of contamination and safeguards public safety.

FATTOM: A Helpful Food Safety Tool

In the food manufacturing industry, controlling potentially harmful and costly microorganisms is crucial for ensuring food safety and quality. The FATTOM acronym – Food, Acidity, Temperature, Time, Oxygen, and Moisture – helps you understand and manage the factors that influence microbial growth. You’ll also see this written as FAT TOM in food safety manuals and training materials; it refers to the same six-factor framework.

This article delves into the meaning and importance of the FATTOM acronym, offering expert insights for food safety & quality assurance professionals on how to effectively control these variables to maintain high standards in food production.

Learn more about the FATTOM acronym in our Microbiology and Food Safety 101 course.

FATTOM Meaning

The acronym FATTOM (aka FAT TOM) represents the six factors that are crucial in determining the growth and survival of microorganisms in food:

- Food: Microorganisms need nutrients to grow, which they get from the food itself.

- Acidity: The pH level of food affects microbial growth, with most pathogens preferring neutral to slightly acidic environments.

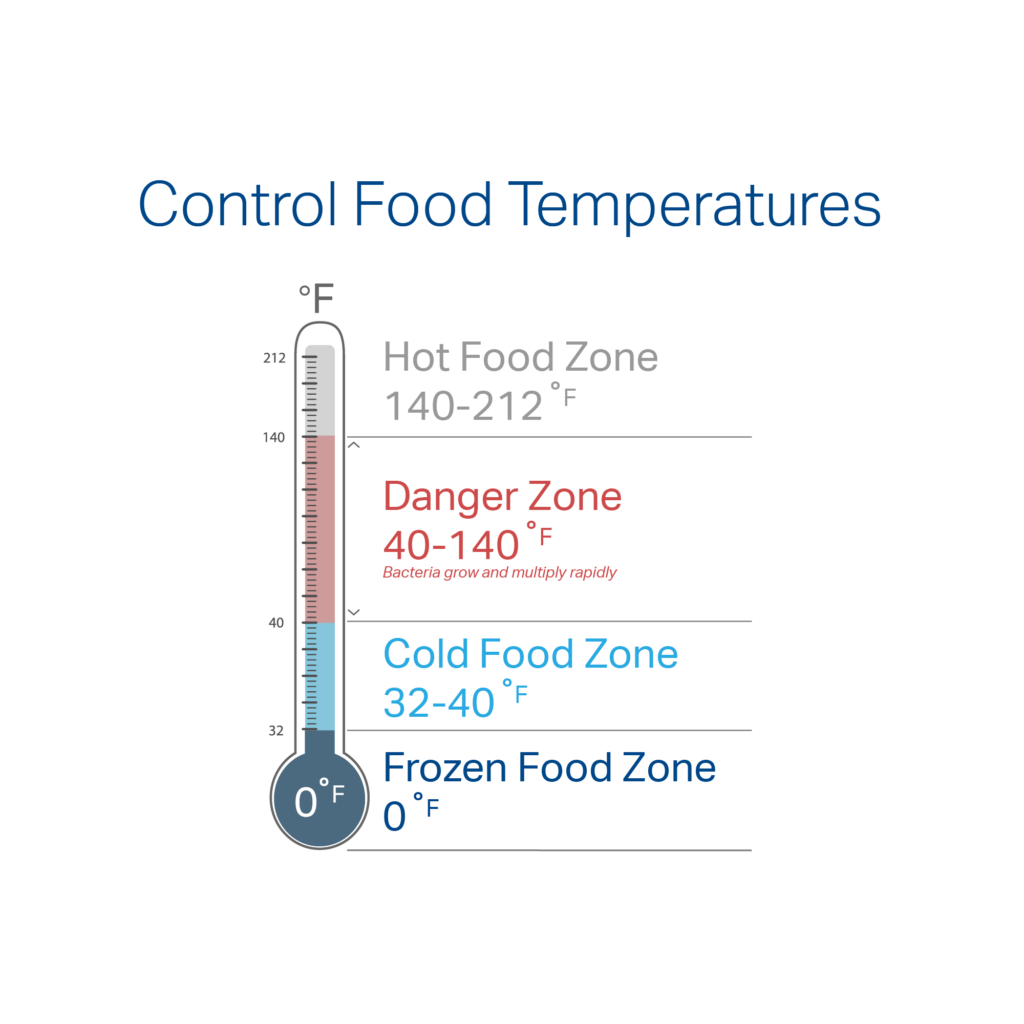

- Temperature: Microorganisms grow best at certain temperatures, often within the “Danger Zone” of 40°F to 140°F (4°C to 60°C).

- Time: The longer food is exposed to optimal growth conditions, the more microorganisms can multiply.

- Oxygen: Some microorganisms require oxygen to grow, while others thrive in its absence.

- Moisture: Water activity (Aw) in food determines the availability of water for microbial growth.

The FATTOM acronym is useful because it helps food safety professionals remember and control the conditions that allow harmful microorganisms to thrive. By managing these six factors, food manufacturers can significantly reduce the risk of foodborne illnesses and spoilage, ensuring safer and higher-quality products.

Let’s take a closer look at each letter of the FATTOM acronym:

F – Food (Nutrients for Microbes)

Microorganisms require nutrients to grow, and they obtain these from the food they contaminate. The key nutrients include:

- Energy sources: Sugars and proteins are primary energy sources for microbial growth.

- Sources of nitrogen: Proteins provide essential nitrogen that microbes need to multiply.

- Vitamins and minerals: These micronutrients support various metabolic activities in microorganisms.

The biological structure of food also plays a significant role. Plants have outer skins that naturally protect against microbial invasion. However, when these skins are damaged or cut, such as when slicing a cantaloupe and “dragging” bacteria onto the flesh of the fruit, the interior becomes exposed and more susceptible to contamination.

Understanding the nutrient needs of microorganisms helps food safety professionals design effective interventions. By controlling nutrient availability through tactics like ingredient selection, preservatives, processing techniques, packaging, and ideal storage conditions, you can minimize the growth of harmful microbes.

A – Acidity (pH)

The acidity, or pH level, of food significantly affects microbial growth. Most microorganisms grow best in neutral to slightly acidic conditions, around pH 7.0. Many pathogens struggle to grow in highly acidic environments.

- Microorganisms thrive at a pH near 7.0. As pH decreases, their growth rate slows.

- Most pathogens do not grow well at pH levels below 4.6, which is why acidic foods like pickles and citrus fruits are less susceptible to contamination. Despite this, some pathogens may survive for a short period at low pH levels.

- Yeasts, molds, and certain spoilage bacteria can grow at lower pH levels, below 4.6, which necessitates additional control measures in acidic foods.

By adjusting the pH level of food, either through natural means (e.g., fermentation) or by adding acids (e.g., vinegar, citric acid), food safety professionals can create environments that inhibit pathogen growth. This approach, combined with other FATTOM factors, helps maintain food safety and extend shelf-life.

T – Temperature

Temperature is a critical factor in microbial growth, influencing the rate at which microorganisms multiply. Controlling temperature is essential to prevent the proliferation of harmful microbes.

Bacterial Classification by Temperature

- Thermophiles: Thrive in very hot environments.

- Mesophiles: Grow best in moderate temperatures, typically between 20°C to 45°C (68°F to 113°F). These include many pathogens.

- Psychrotrophs: Can grow in cold or warm environments, often found in refrigerated foods.

- Psychrophiles: Prefer cold environments, growing well below 20°C (68°F).

Temperature Control

- Refrigeration (< 41°F): Slows or stops the growth of most pathogens. However, psychrotrophs like Listeria monocytogenes, Yersinia enterocolitica, Aeromonas hydrophila, and Clostridium botulinum Type E can still grow slowly.

- Freezing: Inhibits microbial growth but does not kill bacteria. Some bacteria, such as Campylobacter, do not tolerate freezing well and may die.

- Heating: Cooking food to an internal temperature of ≥ 165°F kills most pathogens. Maintaining food at ≥ 140°F prevents the growth and toxin production of remaining microbes.

FATTOM (FAT TOM): Stay Out of the Danger Zone

As mentioned, the temperature range between 40°F and 140°F (4°C to 60°C) is known as the “Danger Zone,” where bacteria can grow rapidly. Minimizing the time food spends in this range is crucial for safety.

When food is heated (cooked) to 165°F and then held at or above 140°F, only spores survive. However, spores can become vegetative cells again if food isn’t cooled quickly enough. Vegetative cells multiply and can produce toxins.

Many bacterial pathogens need time to grow to high enough levels to produce enough toxin to cause disease (i.e. at least four hours in the “Danger Zone”). Some of most common factors leading to foodborne illness are…

- Improper cooling of leftover foods.

- Improper holding temperatures of hot foods, such as hot food buffets.

T – Time

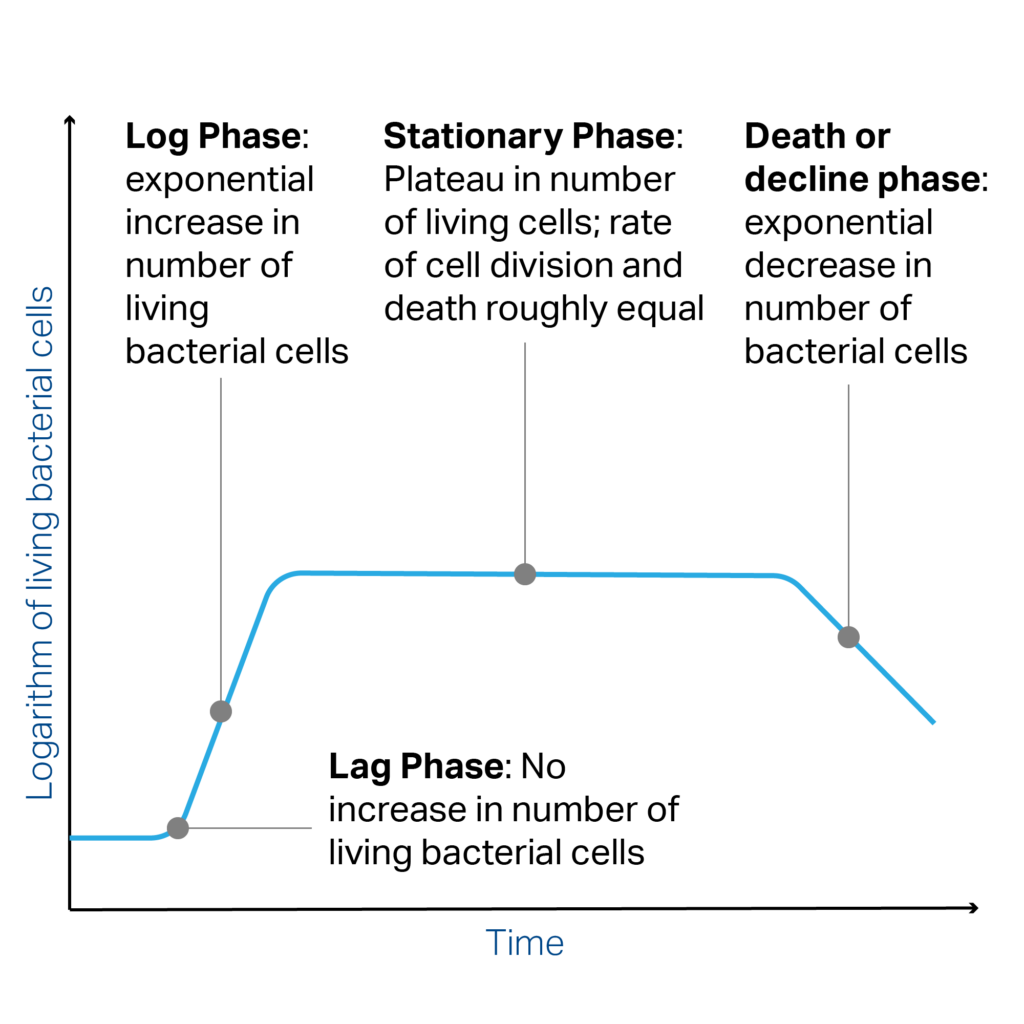

Time is a critical factor in microbial growth, affecting how long microorganisms have to multiply under favorable conditions. Controlling the duration that food spends in optimal growth environments is essential for food safety.

Under ideal conditions, some bacteria can double in number every 15-30 minutes. This rapid multiplication can lead to significant contamination in a short period.

Bacterial Growth Curve

- Lag Phase: Initial period where bacteria adapt to their environment, with little to no cell division.

- Log Phase: Exponential growth phase where bacteria divide rapidly.

- Stationary Phase: Growth rate slows as resources become limited, and the number of new cells equals the number of dying cells.

- Death Phase: Decline in the number of viable bacteria as conditions become unfavorable.

The longer food remains in the “Danger Zone” (40°F – 140°F), the higher the risk of bacterial growth and contamination. Reducing the time food spends in this range is crucial for safety.

Practical Applications for Slowing Bacterial Growth

- After cooking, food should be cooled quickly to below 40°F to minimize time in the Danger Zone.

- Keep cooked food at or above 140°F to prevent bacterial growth.

O – Oxygen (Oxidation-Reduction Potential)

Different microbes have varying oxygen requirements, and controlling oxygen levels helps manage microbial growth.

- Obligate Aerobes: Require oxygen to grow. Examples include Pseudomonas spp. and molds.

- Facultative Anaerobes: Can grow with or without oxygen. Examples include many foodborne pathogens like E. coli and Salmonella.

- Aerotolerant Anaerobes: Do not use oxygen but can tolerate its presence. Lactic acid bacteria fall into this category.

- Obligate Anaerobes: Only grow in the absence of oxygen. Examples include Clostridium spp., which can cause food spoilage and illness.

Practical examples of controlling oxygen levels in food environments include the following:

- Packaging: Modified atmosphere packaging (MAP) and vacuum packaging adjust the gas composition or remove air to reduce oxygen levels, slowing the growth of aerobic microorganisms and extending shelf-life.

- Storage: Use airtight containers to limit oxygen exposure during storage, reducing the risk of contamination and spoilage.

- Processing: Techniques like canning create anaerobic environments that inhibit aerobic microorganisms but may require additional measures to control anaerobes.

M – Moisture (Water)

Water activity (Aw) measures the availability of water for microbial use, directly affecting their ability to thrive.

Water Availability is broken down into two terms:

- Bound Water: Water that is chemically bound within food and unavailable for microbial growth.

- Free Water: Water that is not bound and is available for microbial use, promoting microbial growth.

Water Activity is defined as the ratio of the vapor pressure of water in the food to the vapor pressure of pure water at the same temperature, ranging from 0.00 (no free water) to 1.00 (all free water).

Lower Aw inhibits microbial growth. Most bacteria require Aw of 0.91 or higher, while molds and yeasts can grow at lower Aw levels.

Food Groups by Water Activity

- 0.98 and above: Fresh meats, fruits, vegetables.

- 0.80 to 0.93: Evaporated milk, tomato paste, bread.

- 0.60 to 0.85: Dried fruits, flour, cereals.

- Below 0.60: Confectionery, chocolate, honey.

Some practical applications for controlling water activity include the following:

- Drying and Dehydration: Reducing the water content in food to lower Aw and inhibit microbial growth. Examples include dried fruits and jerky.

- Addition of Solutes: Adding sugar or salt to food to bind free water and lower Aw, preserving products like jams, jellies, and salted meats.

- Packaging: Using moisture-proof packaging to maintain low Aw levels and prevent moisture ingress.

Safeguarding Public Health through FATTOM Principles

Understanding and applying the FATTOM acronym is essential for food safety & quality assurance professionals. By controlling the factors of Food, Acidity, Temperature, Time, Oxygen, and Moisture, food manufacturers can effectively manage microbial risks.

Implementing FATTOM principles helps deter microbial contamination, enhances food safety, and extends product shelf-life, ultimately safeguarding public health and maintaining industry standards. FSNS offers a full range of microbiology assays to support your safety programs.

What Does FAT TOM Stand For?

FAT TOM stands for Food, Acidity, Temperature, Time, Oxygen, and Moisture – the six factors that affect microbial growth in food.

What are the Six FAT TOM Conditions?

The six FAT TOM conditions are: Food, Acidity, Temperature, Time, Oxygen, and Moisture.

What is the Danger Zone for FAT TOM?

The Danger Zone for FATTOM is the temperature range between 40°F and 140°F (4°C to 60°C), where bacteria can grow rapidly. Minimizing the time food spends in this range is crucial for safety.