Effective environmental monitoring programs are key drivers for ensuring food safety, reducing the risk of foodborne illness and maintaining the integrity of the food supply. Through established sampling plans, harmful contaminants are identified early so that rapid response corrective actions can be initiated.

A critical component to food manufacturing operations, environmental monitoring programs can be cumbersome to implement. Factors such as the location, frequency, and quantity of samples taken need to be addressed. Then, you need results – fast. Any delay when you get positive results for dangerous pathogens such as Listeria, Salmonella and L. monocytogenes costs time, money, reputation, and possibly lives.

FSNS, a Certified Group Company, developed a proprietary software solution to help when performing environmental testing in food manufacturing facilities.

Named emma®, it simplifies environmental monitoring while increasing food safety. Through automation, efficiencies are gained in zoning, scheduling, and sampling, at both routine and random intervals, eliminating the guesswork as to when testing is due.

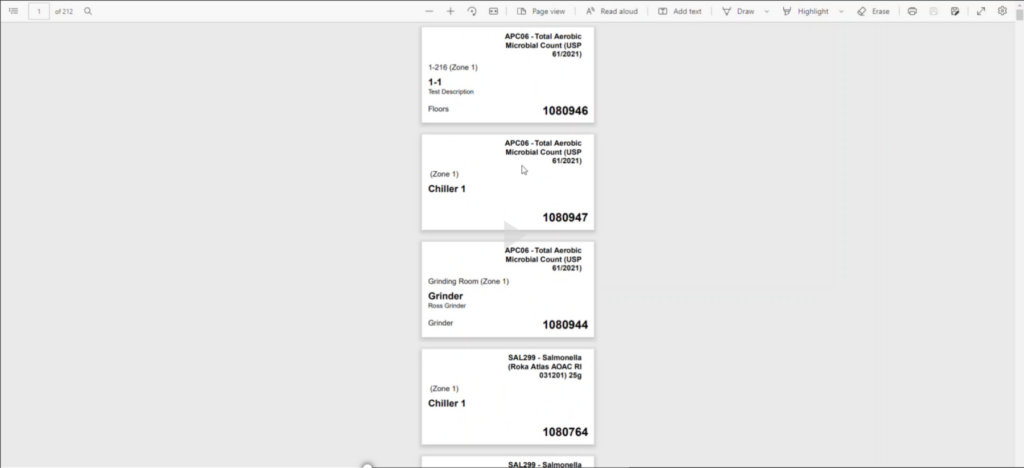

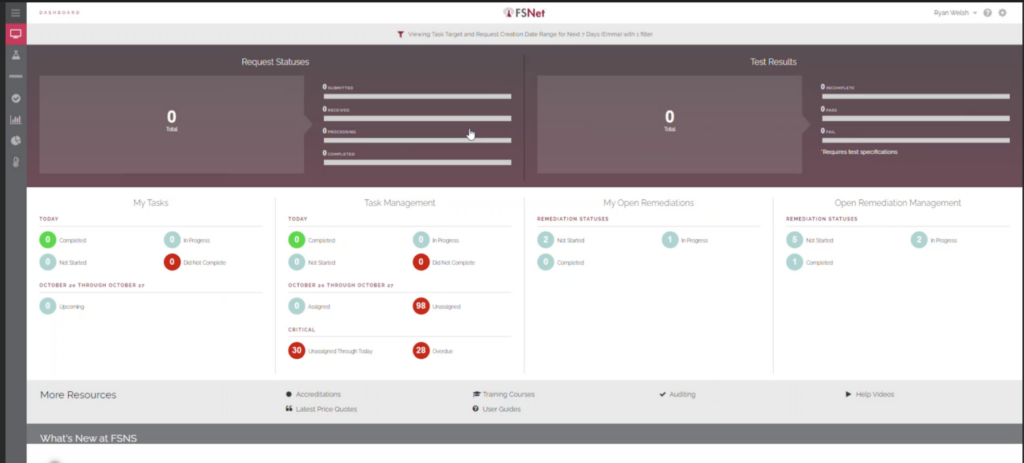

Shipping labels for environmental monitoring samples are automatically printed along with the sampling plan, allowing for expedited return results, displayed via a customized dashboard that offers real-time detailed analytics of swab results. Emma® provides confidence that you environmental monitoring program is working as it should and quickly identifies any need for corrective action.

Why Do I Need an Environmental Monitoring Program?

As an early warning system, an environmental monitoring sampling program is required by the Food and Drug Administration (FDA) as part of a food facility’s Good Manufacturing Practices (GMPs) under the Food Safety Modernization Act (FSMA) to prevent contamination in food processing environments. FSMA requires establishments to develop Hazard Analysis and Risk-Based Preventive Controls that identify potential hazards, their likelihood of occurrence and control procedures as part of a concerted effort to keep risks at bay. When hazards are identified, corrective actions are implemented immediately, eliminating the contaminant and confirming it is no longer a threat.

Introducing emma®, a Game-Changing Proprietary Solution

Emma® is a powerful software solution that efficiently manages all components of an environmental monitoring program, from facility mapping, to sample scheduling, to automatic printing of labels that direct test samples to your trusted partner for environmental testing in food manufacturing, FSNS.

As an environmental monitoring tool, emma® is a one-stop shop. But, its game changing value is its enhanced, real-time reporting via customized dashboards, particularly when early indicators show warning signs of contamination.

How Does emma® Work?

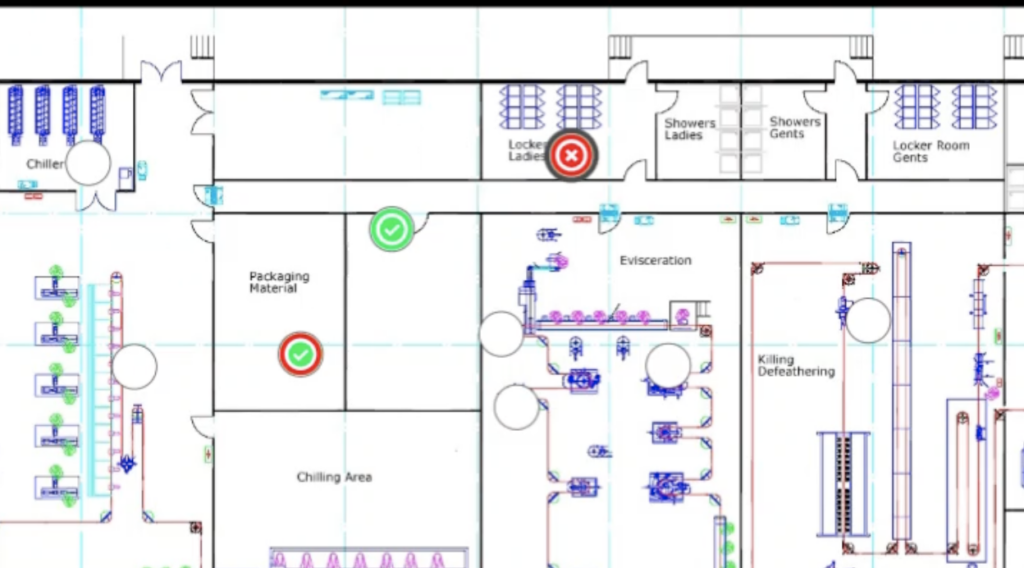

- Food manufacturing plants can use their own facility maps to create diagrams overlaid with unique sample points and environmental testing parameters as determined by the firm’s quality team.

- Routine and random sampling is scheduled, with automatic reminders sent when swabbing at a particular location is due.

- Appropriate labels are formatted and printed with the touch of a button, and sample results are returned via a proprietary customized user dashboard.

Environmental monitoring program results are clearly articulated via our user-friendly interface, delivering easy to visualize pass (green) or fail (red) locations on the facility map. A variety of filters enable an understanding of performance trends over time through a historic playback view.

The result is a safer, FSMA-compliant production facility thanks to an automated environmental monitoring system that provides accurate results quickly.

Key Benefits of emma®

User Friendly: emma® is easy to use and provides multiple benefits over standard environmental monitoring programs. With customizable plans, swab sites and frequencies, your facility’s personalized environmental monitoring program can be created without the use of spreadsheets.

Once emma® is online in a facility, it begins working immediately, alerting to swabbing by zone, logging samples seamlessly into the FSNS LIMS system and uploading quantitative and qualitative results to the user dashboard upon testing completion. A live-action playback mode shows trends, early warning signs and where corrective action is necessary.

Saves Time and Money: All data, tasks and scheduling are kept securely online allowing for easy collection of attributes such as sample point names, zone, rooms and customizable categories. This allows for easier data retrieval analytics via AdHoc reporting features. Our customizable features present your data in meaningful ways.

Simplifies Remediation Management: emma® simplifies remediation management when positive results are returned. Through easy creation of vector sites and corrective actions for failed swab sites, documentation is easily retained in one place. Organizations can pull critical corrective action information for comparison and resolution. There is no limit to uploading supporting documents.

emma® is a powerful ally, particularly during FDA inspections, through a physical demonstration of a robust environmental monitoring and remediation program.

When you are ready to take your environmental monitoring program to the next level, we welcome the opportunity to provide a demo of our proprietary software, emma®. You will experience the effectiveness and efficiency this powerful tool can offer.