Reviewed and Approved by Ryan Welsh, M.S., Corporate Operations Support, Certified Group

1-Minute Summary

- False positives can waste time and money but are not as potentially dangerous to public health as false negatives.

- Positive molecular screens can detect non-viable or stressed microbes that don’t grow in culture, leading to a false positive.

- Cultural confirmation failures can result from selective media challenges or variable growth rates.

- Proper sampling and testing protocols help reduce the risk of false positives and negatives.

- Many organizations treat these cases as presumptive positives and undertake the appropriate mitigation activities.

The Dreaded False Positive (or is it?)

Regardless of your industry, the products you manufacture, or your target organisms, every food safety and quality assurance professional faces the challenge of a false positive at some point. This situation triggers immediate questions and action throughout the organization:

- Do we really have Salmonella, E. coli, Listeria, or another pathogen in our finished product?

- How reliable are these results?

- Could there have been an error during sampling?

In this article, we address a common question our scientists receive at Food Safety Net Services: What should you do when a sample screens positive but confirms negative?

Type I and Type II Errors Explained

First, let’s define the two types of errors that can occur when testing food samples for the presence of pathogens or other organisms.

Type 1 Error (False Positive)

A Type I Error occurs when a test incorrectly indicates the presence of a pathogen or other target organism that is not actually there.

False positives can lead to costly repeat testing, unnecessary sanitation procedures, or even a product recall, disrupting manufacturing and damaging your brand’s reputation. While frustrating, false positives are generally less concerning than Type II Errors.

Type II Error (False Negative)

A Type II Error happens when a test fails to detect a pathogen or other biological hazard that is present.

This poses a significant risk, as contaminated products may be released, potentially leading to foodborne illness outbreaks and regulatory or legal consequences. False negatives can also affect product quality, resulting in negative consumer experiences and reputational harm.

Start with Proper Sampling and Testing Processes

When a positive screen does not confirm culturally, the first step is to evaluate the sampling and testing process:

- Is our definition of a “lot” correct? Are we pulling samples from a representative cross-section of the raw materials, in-process, or finished product?

- Are we processing samples in a clean environment to prevent contamination?

- Is our in-house lab or our third-party lab using aseptic techniques throughout their testing process?

- Is the lab using the correct media, incubation time, or test kits for our target organisms?

- Is staff properly trained?

Various issues can complicate cultural confirmation, such as insufficient target organism presence or interference from background bacteria. Assays may also react with similar organisms, leading to false positives.

The key is to start with the basics to rule out obvious problems.

Is it Really a False Positive – Molecular Methods vs. Traditional Culturing

When samples screen positive but culturally confirm negative, we need to challenge ourselves to think outside the bounds of the traditional “false positive” framework.

Molecular methods used for screening, like PCR, are more sensitive than culturing. They can detect even small amounts of bacterial DNA, including from non-conforming microbes, which are bacteria that carry the target genetic material but do not grow in culture media.

This means a positive molecular test with a negative cultural confirmation doesn’t necessarily mean a “false positive”; it may reflect the presence of non-conforming, non-viable, or stress-adapted microbes.

Overcoming Challenges with Molecular Testing

Given the increased sensitivity and specificity of molecular methods, many think it should be the Gold Standard for food microbiology. Even so, it poses challenges due to the very reasons it is so helpful. Let’s look at a few of them and some possible solutions.

Non-Specific Binding of Primers/Probes

Molecular assays use primers and probes to target specific genetic sequences. However, they may also bind to closely related non-target organisms, amplifying unintended DNA and leading to a false positive.

In this case, carefully design the assay with specific primers and probes. Also, use rigorous inclusivity and exclusivity panels to ensure accuracy.

DNA from Non-Viable Cells

Molecular tests can detect DNA from dead bacteria, especially in samples that have undergone a lethality step, like heat treatment. DNA from these non-viable cells can still trigger a positive molecular result, even though the bacteria are no longer a threat.

One solution is to use methods like Propidium Monoazide (PMA), which binds to DNA that is not inside live cells and prevents the PCR reaction from occurring on that DNA.

Viable but Non-culturable (VBNC)

Many species of organisms, including E. coli, Listeria monocytogenes, and Salmonella, can enter a VBNC state, meaning they are viable but non-culturable.

This means the bacteria are in a very low state of metabolic activity and do not divide. However, they are still alive and can become culturable once resuscitated. They typically don’t grow on standard growth media.

They can enter this state due to all your plant interventions, which stresses them and reduces their rate of nutrient transport, respiration, and macronutrient metabolic activity.

In this case, these actions are helpful:

- Allow additional time to grow in the culture media.

- Regrow with other selective media.

- Screen the sample with an alternative method to obtain more information, such as NeoSeek, Clear Labs, or Droplet Digital PCR.

- Reevaluate following results from other screening methods.

Challenges of Cultural Confirmation

Inherent challenges to cultural confirmation can also lead to what appears to be a false positive.

Issues Due to Selective Media

Selective media is designed to isolate specific bacteria by providing them with the nutrients they need while suppressing others. However, this media can sometimes be too selective.

If bacteria are stressed or injured – due to prior processing conditions, for example – they may not thrive on these media. This can lead to false negatives, where the bacteria are present but fail to grow.

Variable Nutrient Requirements

Furthermore, different strains within the same species, such as Salmonella, may have varying nutrient requirements.

If the media doesn’t cater to these needs, some strains may not grow, even if they are present in the sample. Additionally, the expected chromogenic reactions (color changes) can vary among strains, leading to further identification challenges.

Which Colony do you Choose?

Colony selection adds another layer of complexity.

When plates are overcrowded with mixed bacterial cultures, isolating the target organism can become difficult. Not every colony that appears on the plate represents the target bacteria. Their morphological characteristics – shape, size, and color – can differ significantly depending on the strain and growth conditions. Selecting the wrong colony for further testing can result in a missed detection of the pathogen.

Different Growth Rates

Growth rates also play a significant role.

Not all bacteria grow at the same pace. Slow-growing strains may be overshadowed by more robust competitors, leading to a negative result. Competitive inhibition by other microorganisms can further suppress the growth of the target bacteria, making them harder to isolate.

Salmonella Case Study – Positive Screen Fails to Confirm Culturally

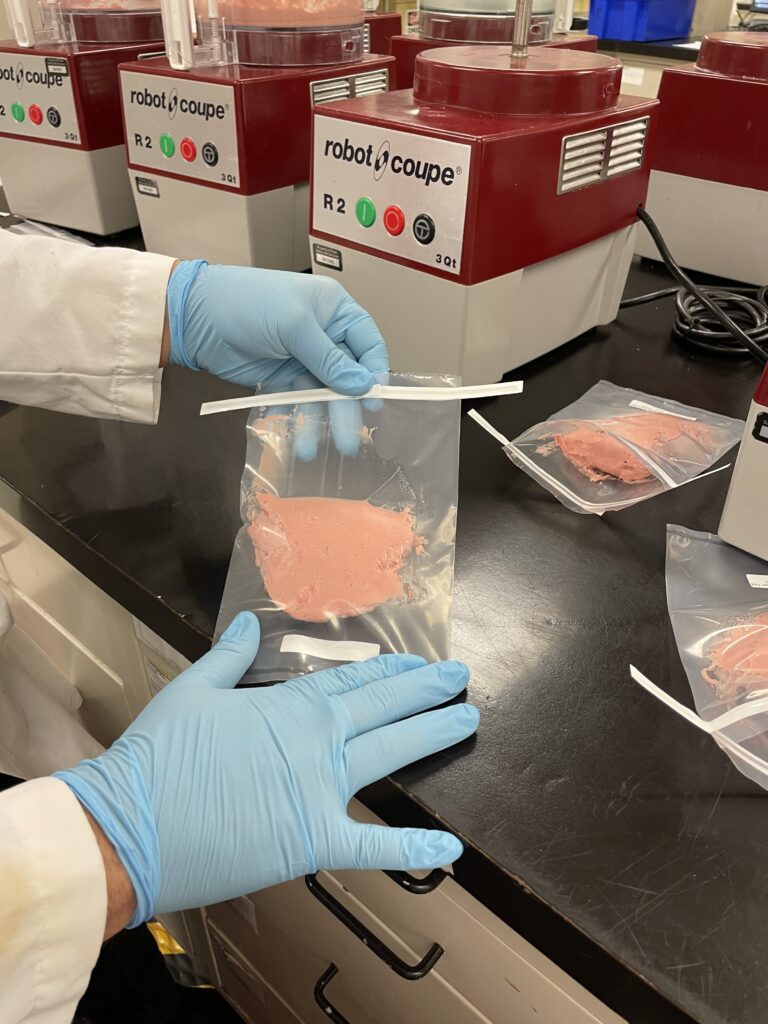

One case involving 40 lots of beef time illustrates many of the points discussed above.

The samples screened positive for Salmonella using a PCR platform. However, all samples failed to confirm culturally using standard USDA MLG procedures, which typically yield a 75-85% confirmation rate. An extensive investigation was conducted to determine the discrepancy between the molecular screening and cultural confirmation results.

The samples were subjected to additional DNA and RNA tests, as well as an immunoassay. All tests confirmed the presence of Salmonella, indicating that the specificity and sensitivity of the original PCR assay were reliable.

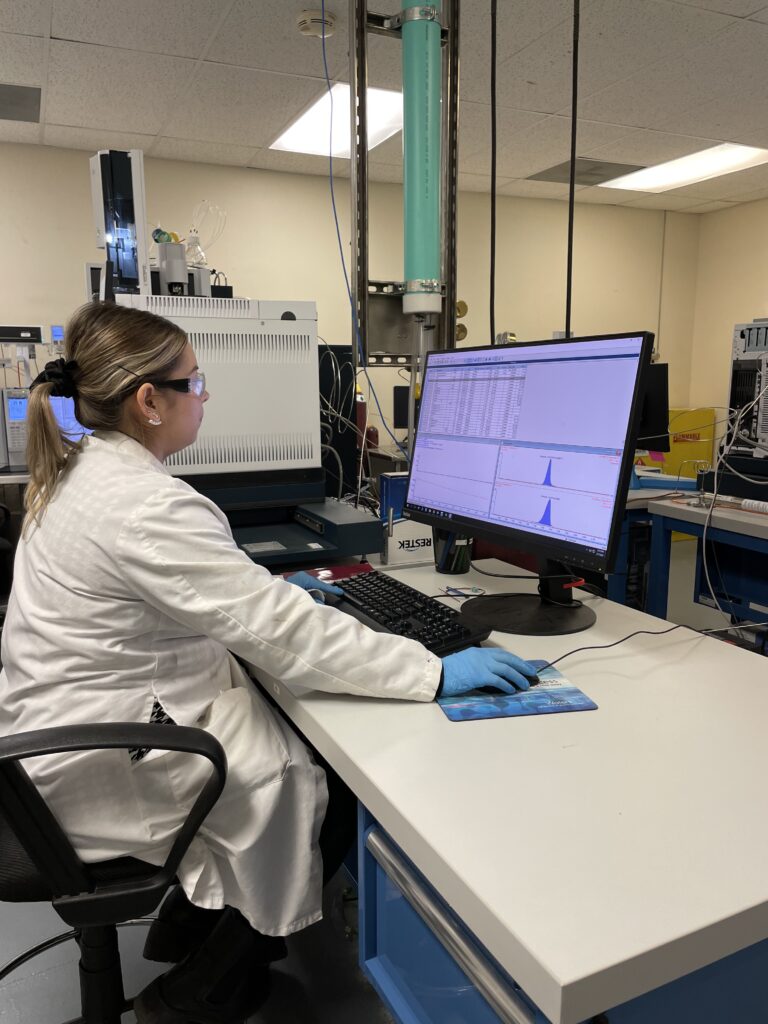

To further explore the cultural confirmation failure, the samples were sent to three different laboratories where a range of plating methods, temperatures, and incubation times were used.

Only 50% of the samples produced isolates initially. Subsequent plating on non-selective media and targeted colony selection resulted in the eventual cultural confirmation of all samples.

Eventually, whole genome sequencing identified the isolate as Salmonella Dublin, a strain known for its challenging growth requirements. This strain’s inability to grow on standard selective media without specific conditions such as extended time and lower temperatures likely contributed to the initial cultural confirmation failure.

This case highlights the limitations of cultural methods when dealing with certain strains and underscores the importance of considering alternative approaches when discrepancies arise between molecular and cultural testing results.

Discrepancies Highlight the Complexity of Food Safety Testing

Given the risk involved for some organizations, many FSQA personnel treat a “false positive” as a presumptive positive to err on the side of caution. This is a good strategy to maximize safety. However, it’s important to understand why you may be getting excessive false positives so your company can control costs and streamline production while still making safe products.

Please contact us if you have questions about your test results or if you need microbiology testing for your products.