Reviewed and Approved by Omar A. Oyarzabal, PhD, Senior Consultant, EAS Consulting Group

1-Minute Summary

- 4 key trends are shaping the beverage industry: new ingredients, clean labels, minimal processing, and increased co-manufacturing.

- New ingredients like ginger, turmeric, flax seed, and others demand safety verification and regulatory compliance.

- Consumers prefer clean labels, but FDA regulations must be met for claims.

- Minimal processing poses safety risks; follow FDA guidelines for new technologies.

- Partnering with co-manufacturers offers growth but complicates safety and quality control.

Navigating Key Trends for Beverage Safety and Growth

To help beverage manufacturers thrive in this evolving industry, our experts identified the following 4 trends that are shaping the industry. While they offer the promise of business growth, you must be sure your products meet safety and quality requirements to take full advantage.

That’s where this guide comes in. It offers advice to help your business manufacture safe products, meet regulatory requirements, and leverage these trends to grow your sales.

As always, contact our experts if you need beverage laboratory testing or regulatory consulting services for foods and beverages to help your business thrive.

Trend 1: Use of New and Non-Traditional Ingredients

Retail shelves are filled with beverages formulated with new and non-traditional ingredients. People can’t get enough of these trendy products formulated to promote health and well-being.

This is especially true when it comes to sweeteners. According to a report by Grand View Research, the global reduced-sugar food & beverages market is expected to grow at a compound annual growth rate (CAGR) of 8.9% from 2022 to 2030. Likewise, Research and Markets predicts the global functional beverages market will grow to $276 billion by 2032 at a CAGR of 6.5%.

To leverage this trend, manufacturers are using a range of novel ingredients that promise improved health, such as…

- Ginger

- Turmeric

- Elderberry

- Probiotics

- Agave

- Hemp

- Monk fruit

- Flax seed powder

Consumers can’t get enough of beverages made with new and non-traditional ingredients that promise health and well-being benefits…but you must ensure that they are safe.

What Does This Mean for Product Safety and Regulatory Requirements?

While it helps for sales, safety should always be at the forefront when using new ingredients. Keep the following in mind:

- Do you have documentation to support the safety of new ingredients?

- Have you conducted laboratory tests using validated methods to verify safety?

- Have you considered the regulatory implications?

Ingredients used in beverages fall under the category of “conventional foods” as defined by the FDA. They are used to sweeten, provide color, enhance flavor, or act as a preservative. So, make sure you have information supporting the safety of new ingredients.

Action Items

- Evaluate the safety of new ingredients through scientific documentation or laboratory testing services for beverages.

- Consult with experts to verify the safety of the ingredients you are planning to use. Our regulatory partners at EAS Consulting Group can help.

Trend 2: The Demand for “Clean” Labels and Fewer “Chemicals”

The trend toward “clean” labels is continuing to reshape the beverage industry. Consumers increasingly want products that contain simple, easily recognizable ingredients instead of what they consider to be “artificial” ingredients.

Consumers are also backing up their desire for transparency and naturalness in their diet with their wallets. According to Food & Beverage Insider, 75% of consumers are willing to pay extra for clean label ingredients.

Understand the Regulations

While the clean label trend offers opportunities for innovation and market differentiation, remember that the FDA regulates the product claims printed on your labels.

Action Items

- Ensure your labels comply with FDA regulations in 21 CFR 101

- Consider reformulating your products to align with the clean label trend and grow sales

This blog post about understanding label claims for food and beverage products provides information to help you understand the regulations.

Trend 3: Less Processing

Minimally processed beverages are popping up everywhere. Claims like “cold-pressed”, and “all natural” suggest healthiness to consumers. Terms in the product name like “naked”, “cleanse”, or “simply” indicate that they’ve been minimally processed and appeal to those seeking a “closer-to-nature” experience.

However, minimal processing could raise significant safety considerations. While the FDA doesn’t mandate thermal processing, strict guidelines must be followed, particularly for juice products that fall under Juice HACCP, which requires a 5-log reduction in the pertinent pathogens.

Newer, non-thermal processing technologies include high pressure processing (HPP), while technologies in development that have not been commercially incorporated yet but have some promise include…

- Pulsed electric fields

- Ultrasound

- Ohmic Heating

- Moderate Electric Fields

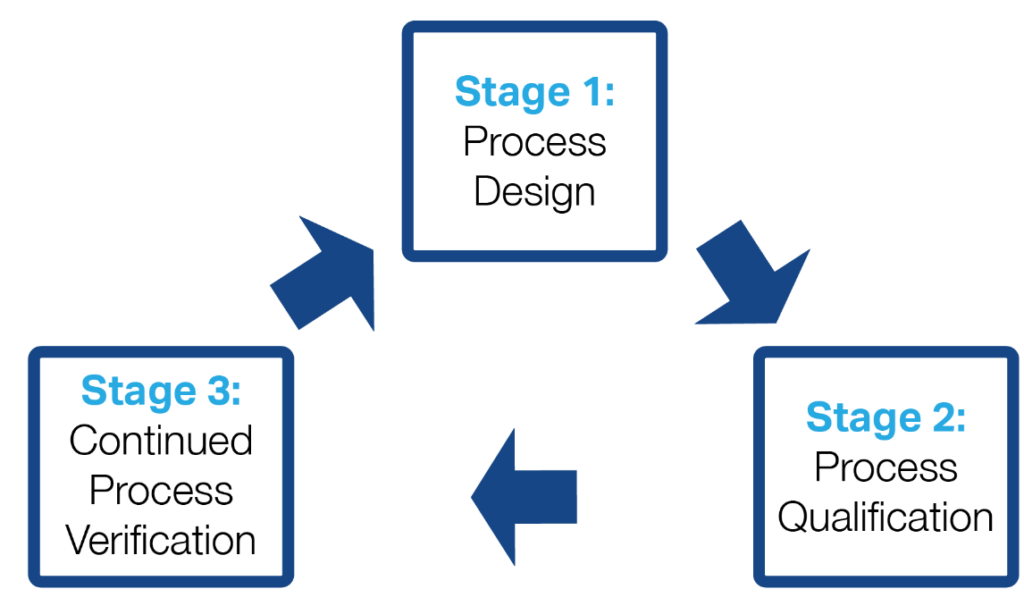

Newer technologies present their own safety and quality challenges. Before revamping your process to include HPP, for instance, get a Processing Authority to review the process and advise on its efficacy. A process validation may also be needed to verify the efficacy of the process. This blog explains how to conduct a process validation for high pressure processing.

After all, what good is a beverage that is “all natural” if it’s not safe to drink?

Action Items

- Engage a Processing Authority to evaluate the efficacy of your planned process based on scientific studies and industry knowledge. This initial review can save you time and money before revamping your entire production process.

- If needed, conduct a process validation to verify the efficacy of your process and generate defensible data to protect your brand.

- Maintain meticulous records of safety tests and validations for each type of minimally processed beverage you produce. This will not only help in regulatory compliance but also provide data-driven insights for internal improvements.

- Periodically review and update your safety procedures in alignment with new research findings, consumer preferences, and technological advancements.

Trend 4: Using and Selecting a Co-Manufacturer

More companies than ever are partnering with co-manufacturers to scale production and broaden market reach. While this approach has advantages, such as speed-to-market and cost-effectiveness, it also complicates the landscape for safety and quality control.

The following list helps you establish ideas on how to start vetting co-manufacturers. This approach will help ensure regulatory compliance and consumer trust in your brand.

Safety Framework & Action Items

FSMA Compliance: Ensure the co-manufacturer is fully compliant with the appropriate regulations covering their products.

- If possible, conduct an on-site audit for thorough verification.

- Ask to see their food safety plan, including hazard analysis, as well as documentation about the verification of their suppliers.

Food Safety Certifications: Good Manufacturing Practices (GMP) certification or other certifications from the Global Food Safety Initiative are important to show a co-manufacturer’s commitment to safety and quality.

- Inquire if the facility has had any recent inspections by state or federal inspectors. Ask for any reports from these inspections.

- Inquire about audit reports and any corrective actions taken.

Technology & Equipment: Verify that the co-manufacturer has the technological capabilities for the safe manufacturing of your beverages.

- Conduct pilot tests with your specific product to validate both the equipment and the expertise of the co-manufacturer in handling your production needs.

Processing Authority Review: Complement in-house reviews with an external Processing Authority’s evaluation for unbiased, specialized insights.

- Have a third-party Processing Authority review the co-manufacturer’s safety protocols and specialized processes relevant to your product. This review can help you made a sound judgement about the co-manufacturer’s capabilities.

Raw Material Traceability: Ensure the potential co-manufacturer has a robust traceability system in place.

- Discuss contingency plans for potential safety failures or recalls with the co-manufacturer.

Embrace Innovation with Expert Support

As industry trends continue to evolve, it’s crucial to remain informed and prepared.

For comprehensive laboratory testing for beverage safety, contract research including process validations, or expert regulatory consulting, reach out to us. We’re here to help your business meet regulations, cater to consumer demand, and thrive in a competitive market.